HR-IVA® (High Resolution IVA® Testing)

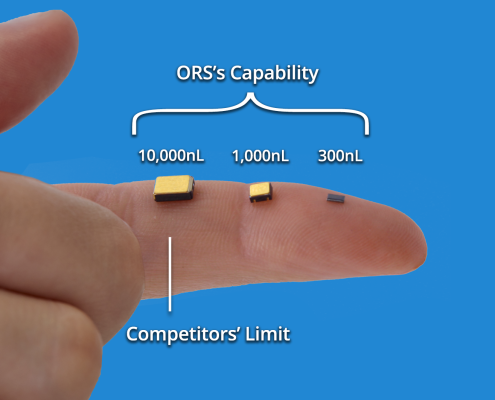

ORS is now DLA suitable to test cavity volumes as low as 300nL

As technological advances create smaller and smaller cavity volume devices, the test equipment used to measure and control the gas needs to keep pace.

ORS leads the industry in Residual Gas Analysis (RGA) testing, which is also referred to as Internal Vapor Analysis (IVA®). IVA® has been a core technology of ORS for over 45 years. The high-resolution, time-of-flight mass spectrometer system is used for measuring gas content of samples with an internal free cavity volume as small as 1nL (1×10-6cc).

ORS is currently the only lab that can measure gas volumes as low as 300nL in compliance with DLA-approved MIL-STD methods. Our competitors are limited to testing components with volumes greater than or equal to 10,000nL (0.01cc) with older technology.

ORS has Suitability status from the Defense Logistics Agency (DLA) for qualifying military devices according to MIL-STD 750 and 883 method 1018. Our DLA Suitability status is intended for the qualification of military devices and we are prohibited from changing any test parameters described within the method. However, there are instances where the test parameters used for military applications are inappropriate for commercial product or process development studies (e.g., sample test temperature and sample pre-bake requirements) – MEMS, implantable medical devices (Pacemakers), automotive and telecom devices. For commercial applications, we conduct the test per our Commercial Practice Test Method MEL-1053.

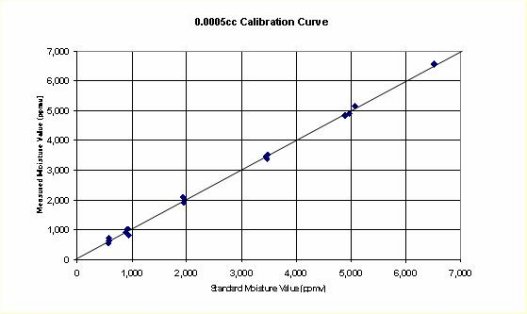

The Commercial Practice Test Method MEL-1053 exceeds the instrument and calibration requirements of the Military Standards. The ORS commercial practice test method represents best practices for R&D and process monitoring applications.

High-precision test equipment for low-volume packages

In a world of shrinking devices, ORS has created the test equipment needed to quantify the gas content of extremely small volumes. We built the HR-IVA® Analyzer specifically for testing gases in very small or vacuum-sealed package cavities. This new technology provides tremendous sensitivity to package volumes < 0.01cc (as low as 1nL) compared to standard Quadrupole techniques, which are applicable to samples equal to or larger than 0.01cc. In a three-year development program to address industry trends to manufacture smaller and smaller devices, ORS has developed innovative calibration and testing technology for measuring small volume devices. We developed all-metal seal calibrator technology that allows us to calibrate the system at volumes ranging from 0.01cc (10,000nL) down to 100nL (1×10-6cc). We developed a high-speed, high-mass resolution and highly sensitive Time-Of-Flight (TOF) spectrometer to test the tiniest of devices with significant advancement in signal-to-noise. And we are the only DLA-suitable laboratory qualified to test device cavities <0.01cc (as low as 0.0003cc). HR-IVA® System Specifications

- Spectra acquisition speed: 1 full spectra every 20 µs

- Mass range: mass 2 to 150 standard (2-500 capable)

- Mass resolution: 0.1 AMU

- Calibration fixtures: 0.0001, 0.0003, 0.0005, 0.001, 0.005 and 0.01cc

- Single sample mounting procedure

- Sample temperature: 100°C standard (room temperature to 150°C capable)

- Sample internal free volume: 1nl (1×10-6cc) to infinite volume

- DLA suitable range as low as 0.0003cc

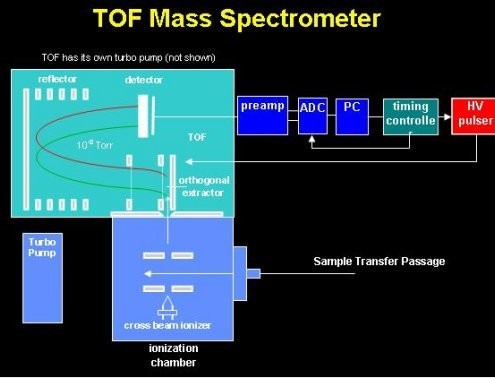

The sample gas from the device passes through a small transfer passage into the ion source. As the sample gas passes by, ions of the gas are created. Every 20 µs, a packet of ions are extracted into the TOF by a high-voltage pulse. The ions then traverse the flight path to the ion count detector. The time that it takes each ion to reach the detector is related to the mass-to-charge ratio. Ions reaching the detector are counted and saved in the PC at a 2 GHz sampling rate.