UHV-EGA MODEL 510 ULTRA-HIGH VACUUM EVOLVED GAS ANALYZER

The UHV-EGA Model 510 is a state-of-the-art Ultra-High Vacuum Evolved Gas Analyzer. The UHV-EGA technique is also known as thermal desorption spectroscopy (TDS). This advanced instrument uses mass spectrometry to identify evolved gases from solid or highly viscous samples. Samples under test are exposed to a temperature profile under high vacuum conditions. The results of the testing can determine a materials thermal variant. Outgassing rates can also be determined.

The UHV-EGA model 510 instrument is designed to precisely evaluate how material outgassing properties change when exposed to a different temperature or temperature profile under high vacuum conditions.

Utilizing ORS’ expert knowledge of mass spectrometry and quantitative analysis of low molecular weight gases, this user-friendly instrument has been designed to study the thermal or chemical properties of a material. The UHV-EGA Model 510 is driven by a custom software package with integrated temperature control and data acquisition software. Custom designed test enclosures can be manufactured per client needs.

Key Features

- High Temperature Capability: The UHV-EGA can subject samples to temperatures up to 1200°C, making it suitable for analyzing a wide range of materials.

- Ultra-High Vacuum: Operates under vacuum conditions of approximately <5E-8 Torr to minimize contamination and enhance analysis accuracy.

- Dynamic Ramp Rates: Supports temperature ramp rates from 0.1°C to 15°C per minute, allowing for customizable analysis.

- Wide Adjustable Mass Range: Equipped with a quadrupole mass spectrometer that covers a mass range of 1-300 amu.

Request an UHV-EGA Demo or Follow-Up Call

Our UHV-EGA model 510® system offers the most accurate and reproducible data in the industry. Let us show you how easy it is!

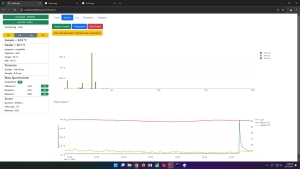

EVACSTM : A dedicated software to operate EGA-UHV instrument with ease. The user friendly software is developed to load/unload sample, tune the mass spectrometer, monitor vacuum conditions and set up heating procedures.

- System Specifications

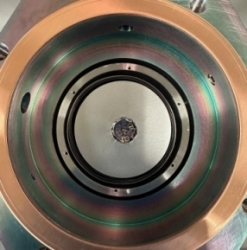

- Sample Size: Can analyze solid or semi-solid samples placed on a 2” diameter heater with a 2.375” headspace.

- Analytical Capability: Measures total gas pressure, heater temperature, sample temperature, and ion count across the entire mass range.

- Comprehensive Software: For easy sample loading, setting up variety of heating and analytical protocols.

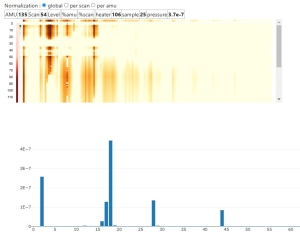

- Accurate Data Acquisition: With real-time 2D and 3D visualization of acquired data during analysis

- Smart Interlock System: To protect the unit from power failures, operator errors and hardware failures

- Applications

The UHV-EGA 510 is essential for various industries, particularly those involved in hermetically sealed microelectronics packages and products for ultra-high vacuum applications. Key applications include:

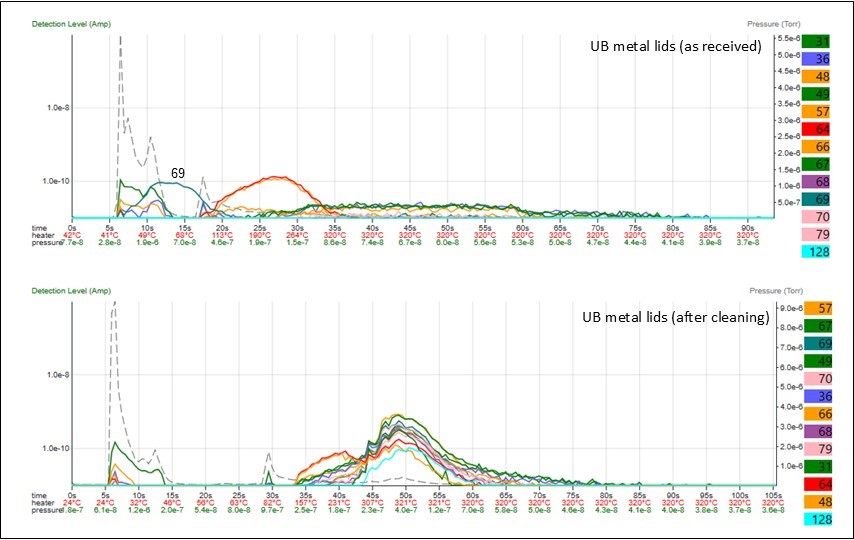

- Contaminant Detection: Identifies and quantifies contaminants such as moisture, hydrogen, oxygen, hydrocarbons, and other volatiles that can affect device performance in sealed or UHV conditions.

- Failure Mechanism Analysis: Helps identify potential failure mechanisms like corrosion, electrical leakage, and dendritic growth by analyzing evolved gases.

- Quality Control: Ensures materials and processes do not introduce harmful volatiles into sealed packages or in UHV conditions, thus maintaining high reliability standards.

- Process Improvement: Facilitates the creation of efficient thermal processing methods and improves product quality by simulating the baking process at the component level.