Delta-P Getter Sorption Qualification Testing

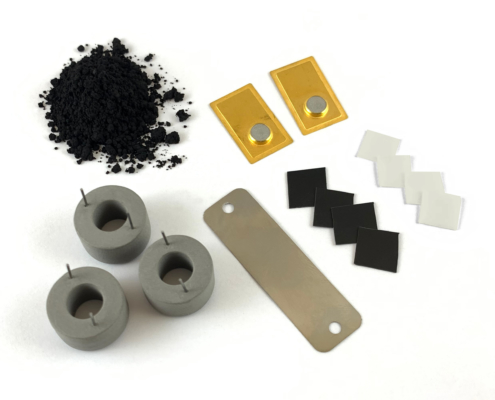

Getter Sorption Testing (also known as Delta-P Testing) is a getter qualification test and lot conformance test used on getter materials including hydrogen getters and moisture getters to provide safer operational environments for the cryogenic, nuclear, aerospace and defense industries. Getter Sorption Testing measures the sorption speed, capacity and lifetime of hydrogen (H2), oxygen (O2), carbon dioxide (CO2), nitrogen (N2), carbon monoxide (CO) and organic getters in a sealed chamber. Our accurate and precise test results provide our clients with the necessary data to qualify and verify the performance of batches of getter material at a wide range of operating conditions.

Hydrogen getters are critical in eliminating failures in microelectronics, cryogenics and energy storage systems. A getter, including nonevaporable getters that act as a getter vacuum pump, is typically a reactive material that is placed inside a closed system to maintain a vacuum or other desired gas composition. When molecules strike the getter material, they combine with it by both adsorption and absorption. This process of removing residual gas in this way is known as gettering or getter vacuum pumping.

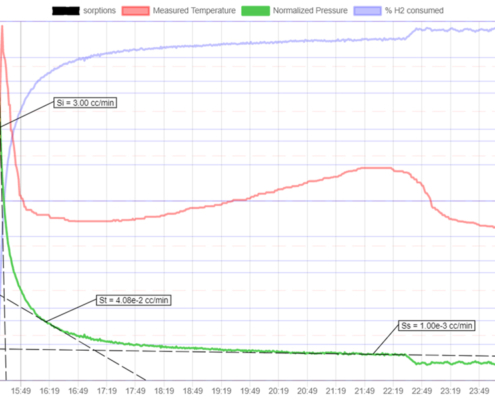

Hydrogen sorption rates can be determined by the change in pressure or Delta-P in a test chamber of constant volume and temperature over time. Delta-P Sorption Testing is applicable for three primary types of hydrogen sorption:

- Hydride Sorption – When hydrogen is absorbed into a metal through gettering

- Sorption by Reduction – When a metal oxide reacts with hydrogen to create a pure metal and water vapor

- Hydrogenation Sorption – When hydrogen is absorbed into a getter to counteract the creation of water vapor

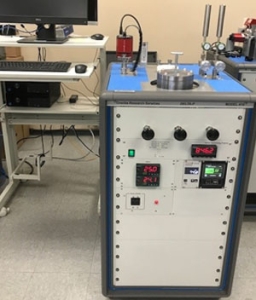

ORS Delta-P Getter Sorption Test System

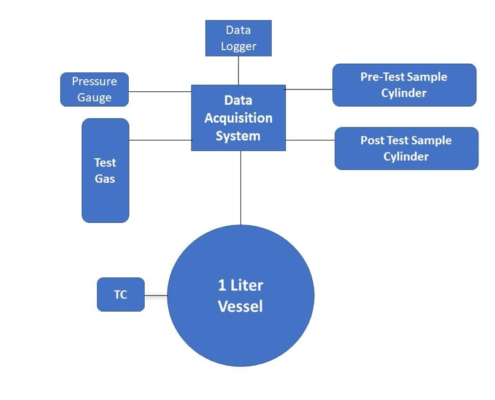

ORS’s Delta-P Model 410 test system is used for getter qualification testing and consists of a test chamber, a data acquisition system, various sensors, and the associated plumbing to introduce, vent and sample the test gas. Getter sorption testing is necessary to verify lot to lot conformance and to identify changes in vendor processes. See the diagram below for how this all fits together.

In testing, the first step is to seal the hydrogen getter or moisture getter in a test chamber that is set at a designated temperature and evacuated to < 1 torr or purged with a dry gas mixture. A pre-test getter activation step at temperature may be required. In the case of a hydrogen getter or hydrogen absorber, a 3% or lower certified hydrogen test gas mix is introduced into the vessel at a specified pressure. A hydrogen concentration of 3% or lower is required to ensure that the hydrogen concentration in the test system is below the lower flammability limit for hydrogen of 4%. Pressure and temperature data are then collected for the specified duration to obtain a proper hydrogen sorption curve. Gas samples are taken pre and post test to quantify the gas concentration changes from the getter sorption reactions. Getter gas analysis is important to identify outgassing substances when using a polymer matrix. Rates of hydrogen sorption and unwanted chemical reactions may be identified when material is subjected to high temperature or environmental liquids like brine water.

Typical Delta-P Sorption Curve

Delta-P Getter Sorption Test Conditions

- Test Temperature: -40C to 900C

- Getter Activation Temperature: up to 900C

- Fill Pressure: 0 torr to 1520 torr

- Chamber Volume: up to 1 Liter

Delta-P Test Results

- Initial, transitional and long-term getter sorption rates

- Getter sorption capacity

- Quantity of hydrogen sorbed

- Pre- and post-test gas analysis results utilizing Internal Vapor Analysis

Pre-Conditioning Service

If you need help with pre-conditioning getter samples, we can perform environmental exposure studies utilizing high-pressure exposure and/or high temperature exposure. Exposing a getter to these conditions shows how they will effect its efficiency and long-term stability. Our system goes up to 12 bar and 500 C.

Request a Demo or Call

Our highly precise Getter Sorption testing gives you the data you need to qualify and verify the performance of batches of getters at a wide range of operating conditions. We’re happy to talk you through how it all works.