Destructive Physical Analysis (DPA) Testing for Capacitors

In today’s modern world of technology, capacitors are still considered one of the three fundamental passive elements needed to build a viable circuit. It is no wonder that the history of a capacitor dates back to as early as 1745!

A capacitor is a passive device used for storing electrical energy. In its most rudimentary form, a capacitor consists of two or more parallel plates (typically metal) separated by an insulating material. The insulating material is referred to as the dielectric; whereas the plates are considered electrodes.

A wide variety of dielectric and electrode combinations exist to form various types of capacitors. Typical types of capacitors are:

- Ceramic (most typical)

- Mica

- Tantalum (solid)

- Tantalum slug (wet)

- Metal Film/Foil

- Paper/Plastic Film

- Glass

The downsizing and weight reduction required for many electronic products wouldn’t have been possible without miniaturizing MLCCs (multilayer ceramic capacitors). Today, hundreds of MLCCs are used for mobile phones and thousands can be used for PCs or even gaming consoles. Can you imagine how many MLCCs are used for space or defense designs?

A typical ceramic capacitor is made of BME (base metal electrodes) or PME (precious metal electrodes), the dielectric is ceramic. Precious metal electrodes typically use metals such as Silver-Palladium (AgPd). Whereas, base metal electrodes are usually comprised of less expensive metals like Nickel (Ni) or Copper (Cu).

Typical non-destructive tests for capacitors include external visual examination, X-radiography, hermeticity testing and prohibited material inspection. However, given the capacitor construction some non-destructive tests are not applicable. Destructive testing usually requires a cross-section and inspection; in some cases de-encapsulation or de-lid is performed to inspect internal surfaces. For leaded devices, it is likely that terminal strength testing or lead pull testing is to be performed.

Contact us for information about capacitor testing

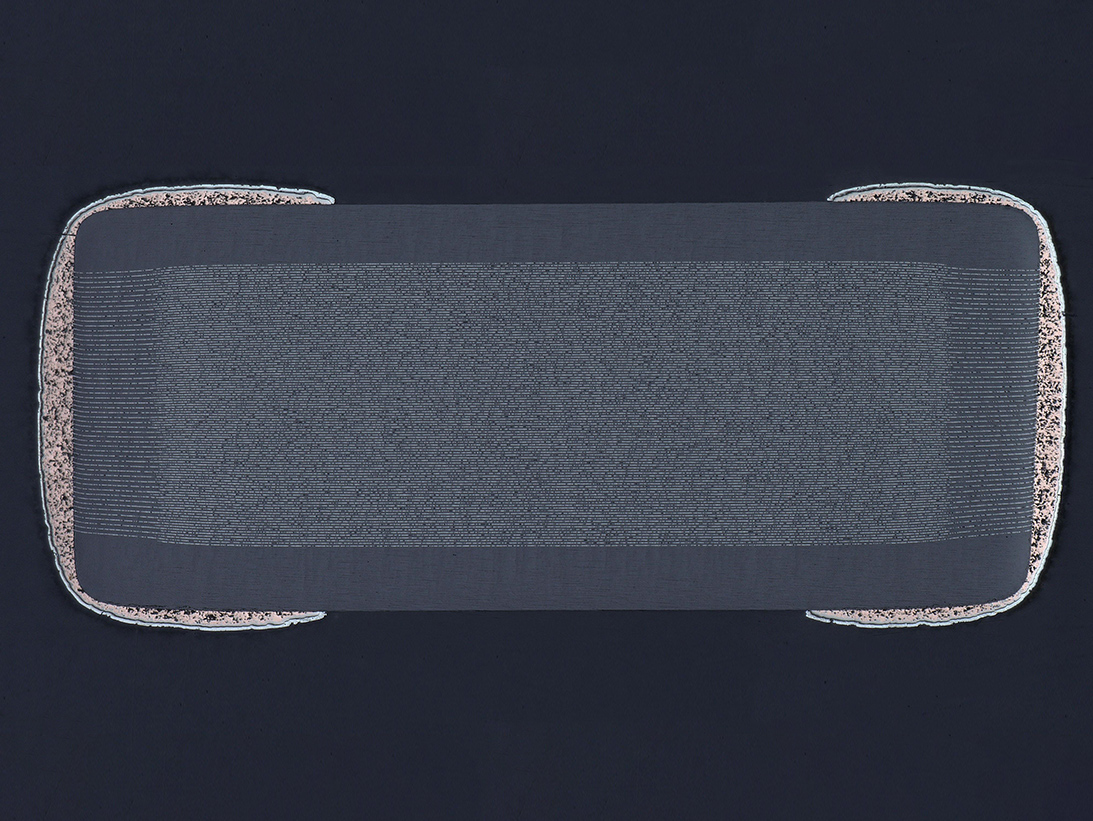

Optical image of a ceramic chip capacitor; longitudinal cut cross-section

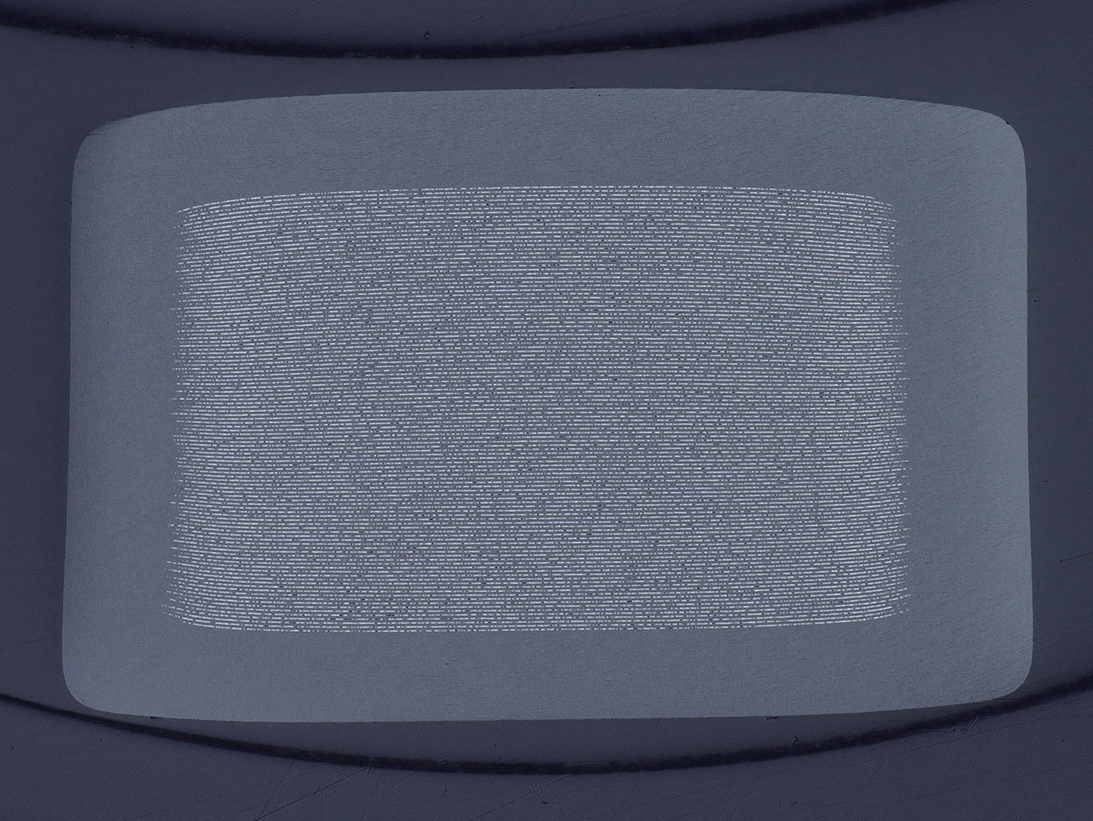

Optical image of a ceramic chip capacitor; transverse cut cross-section

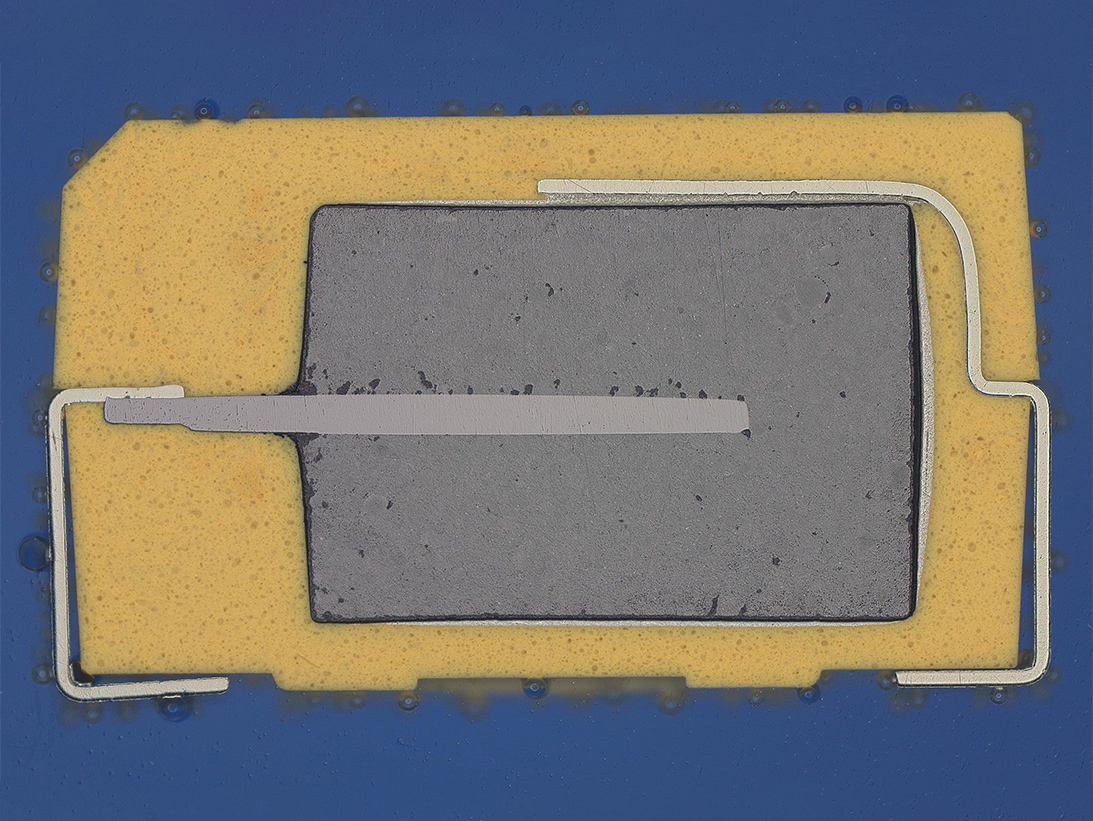

Optical image of a tantalum chip capacitor; longitudinal cross-section

Failure modes/Anomalous Findings:

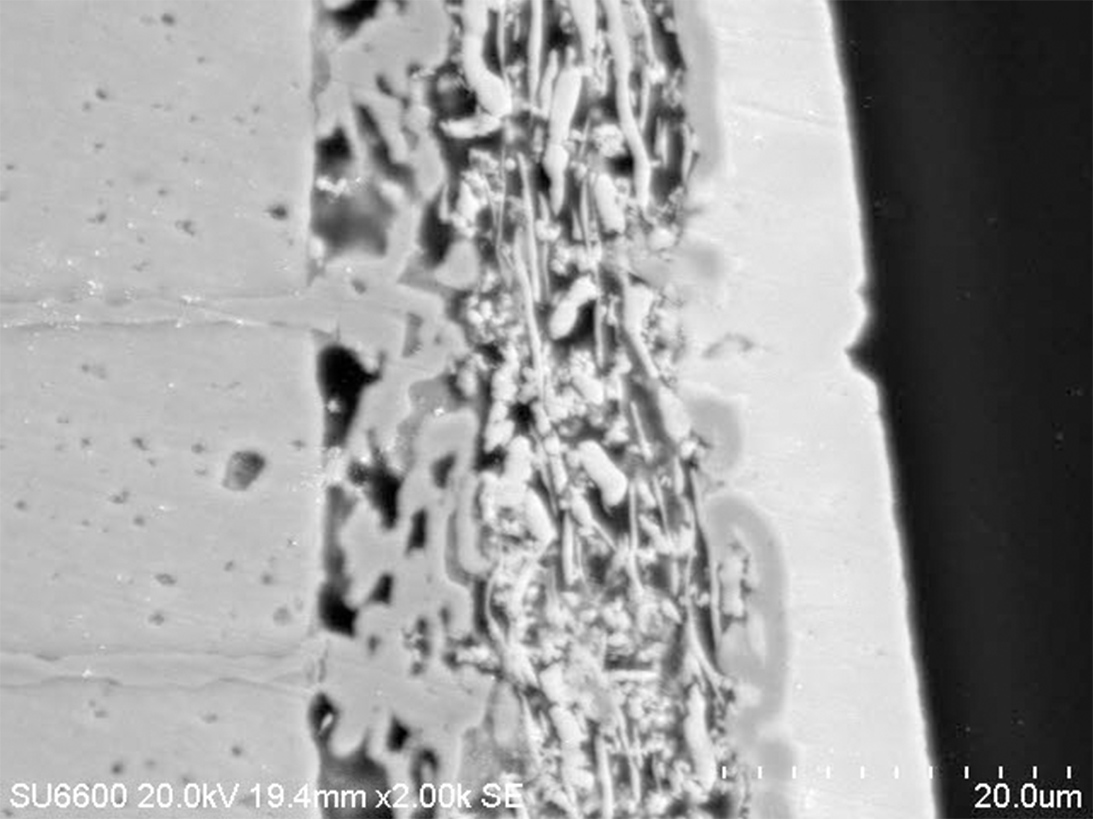

Discontinuous barrier layer

Warpage

DPA Test Methods:

Several capacitor types are covered within Mil-Std-1580 revision C, Requirement 10.

Ceramic monolithic capacitors are also covered within ANSI EIA-469-E.

The following DLA performance specifications are available for capacitors:

- Mil-Prf-123 – Fixed, ceramic (temperature stable and general purpose)

- Mil-Prf-20 – Fixed, ceramic (temperature compensating)

- Mil-Prf-39014 – Fixed, ceramic (general purpose)

- Mil-Prf-49470 – Fixed, ceramic, switch mode power supply (temperature stable & general purpose)

- Mil-Prf-55681 – Fixed, ceramic, chip

- Mil-Prf-32535 – Fixed, ceramic, chip, extended range (temperature stable & general purpose)

- Mil-Prf-23269 – Fixed, glass dielectric

- Mil-Prf-39006 – Fixed, electrolytic (nonsolid), tantalum

- Mil-Prf-55365 – Fixed, electrolytic (tantalum), chip

- Mil-Prf-14409 – Variable, (piston type, tubular trimmer)

- Mil-Prf-49464 – Fixed, chip, single layer, parallel plate

- Mil-Prf-19978 – Fixed, plastic (or paper-plastic) dielectric

- Mil-Prf-83421 – Fixed, metallized plastic film dielectric