Destructive Physical Analysis (DPA) Testing for Diodes

Diodes are a basic fundamental component used to serve various functional applications in nearly all electronic circuits. Due to the wide-ranging applications, multiple construction configurations exist.

Typical diode packages (i.e., glass bodied, various metal TOs with lid welds, glass seals and plastic encapsulated devices) are prevalent in Aerospace, Military and Automotive systems and are subject to qualification requirements based on MIL-PRF-19500, and DPA MIL-STD-1580 and MIL-STD-750.

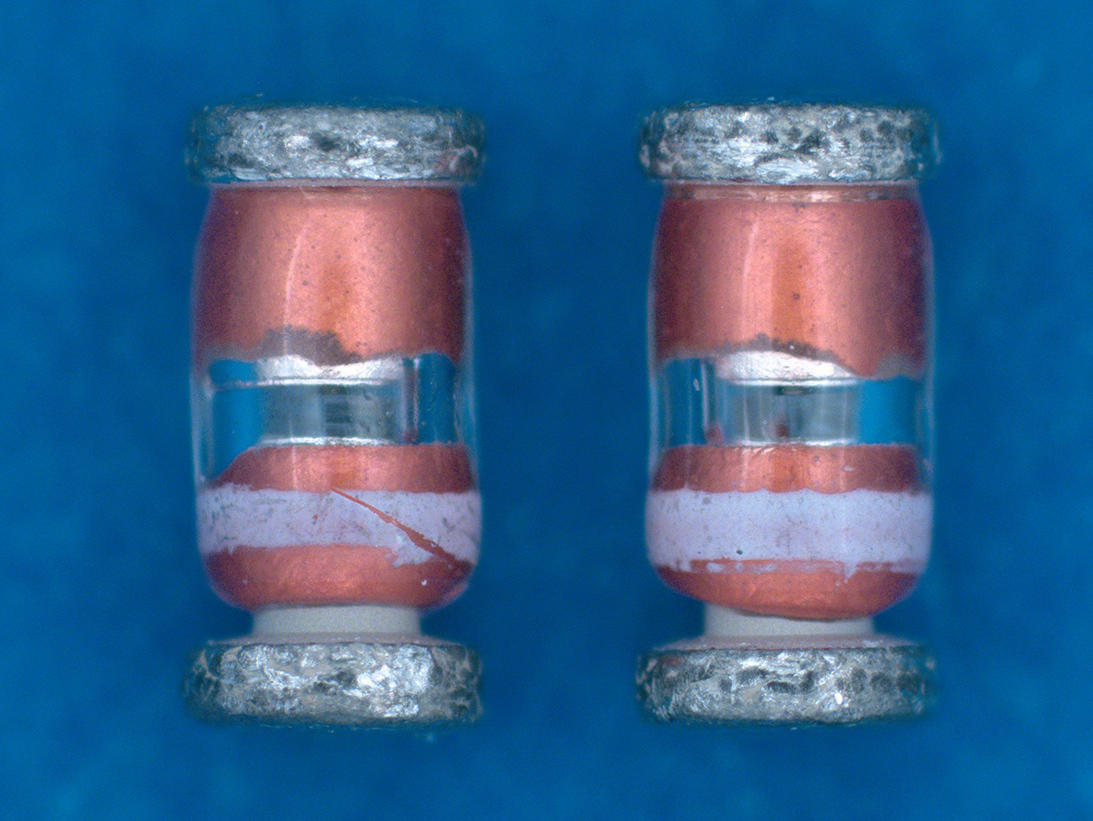

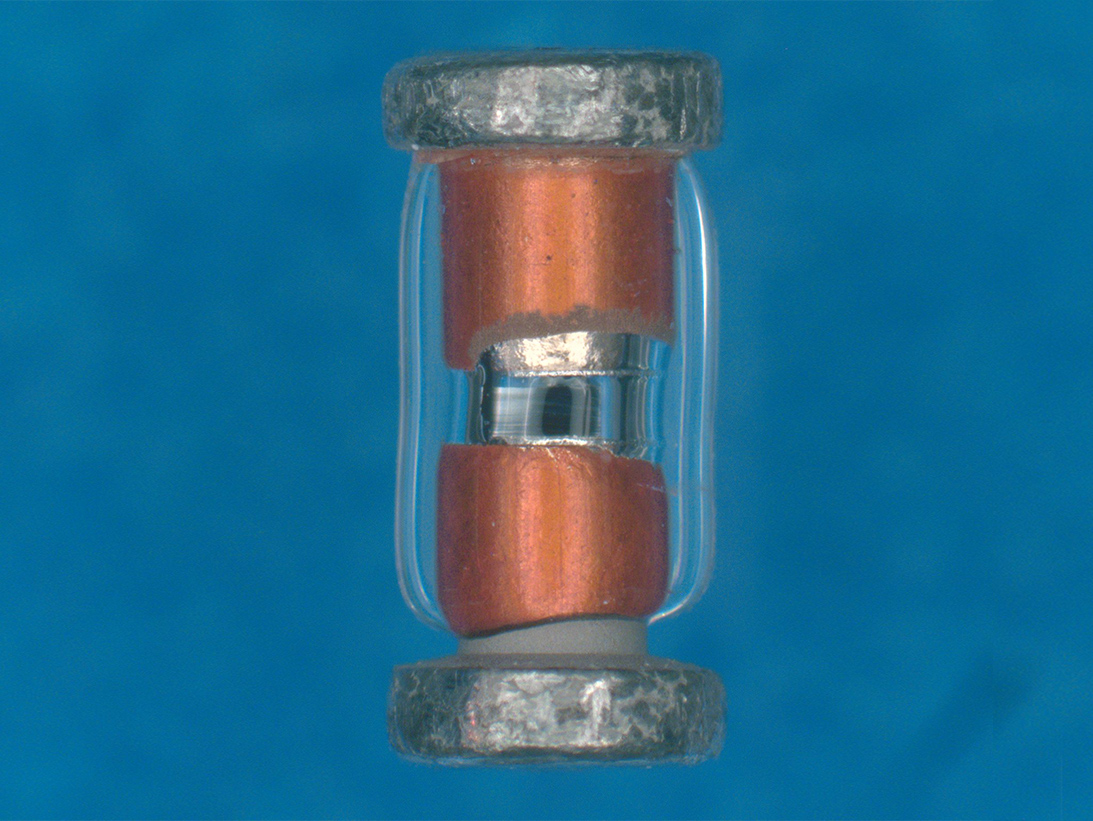

Glass Bodied

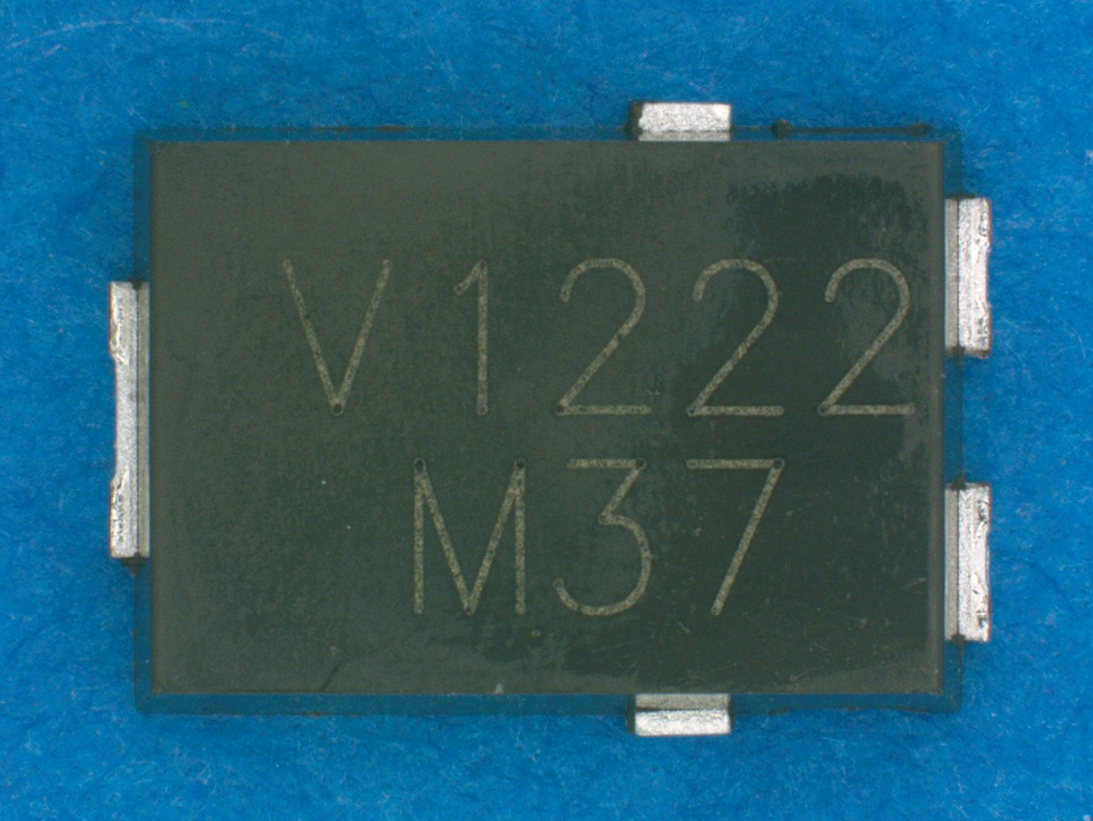

Plastic DO-219

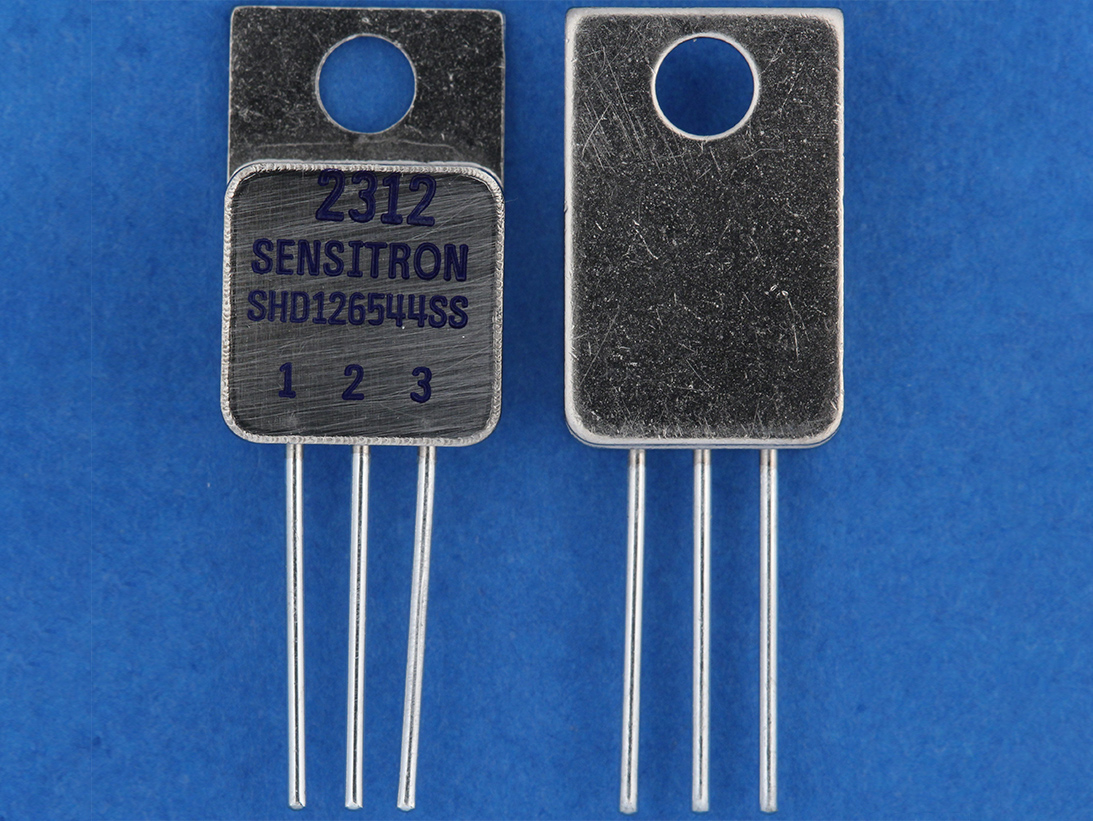

Metal TO-257

ORS Offers FAST Reliable Diode DPA

Diode device construction variations require specific test methods in a DPA test flow.

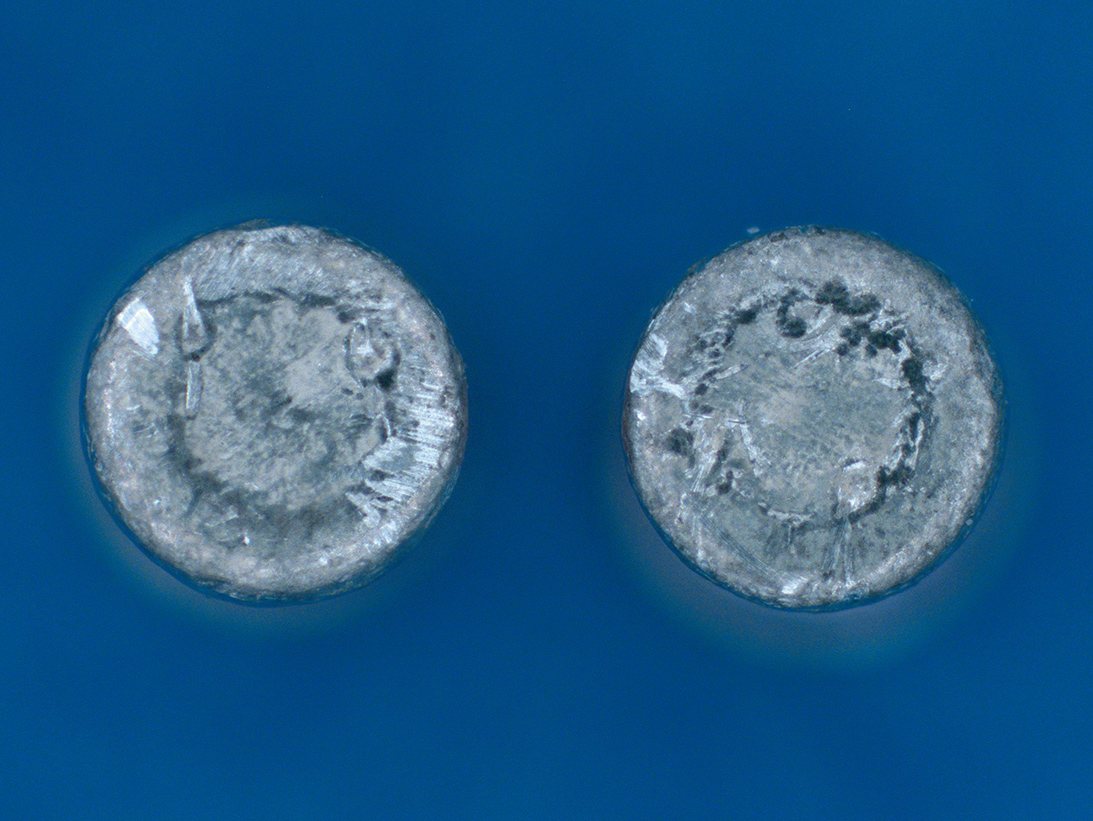

MIL-STD-1580 Requirement 13.1 for glass-body diodes requires testing to Method 2101 of MIL-STD-750 and forward voltage and reverse leak measurements for confirmation of dye attachment as well as scribe and break testing and cross-sectional inspection. Gross-leak testing by dye penetrant and inspection under fluorescent lighting is also required.

Hermetic packages require testing to Method 2102 of MIL-STD-750 that includes Hermeticity testing, Method 1071 and IGA testing Method 1018, and possibly bond strength and dye shear testing methods 2037 and 2017. Overlay integrity and SEM metal inspection may be applicable as well.

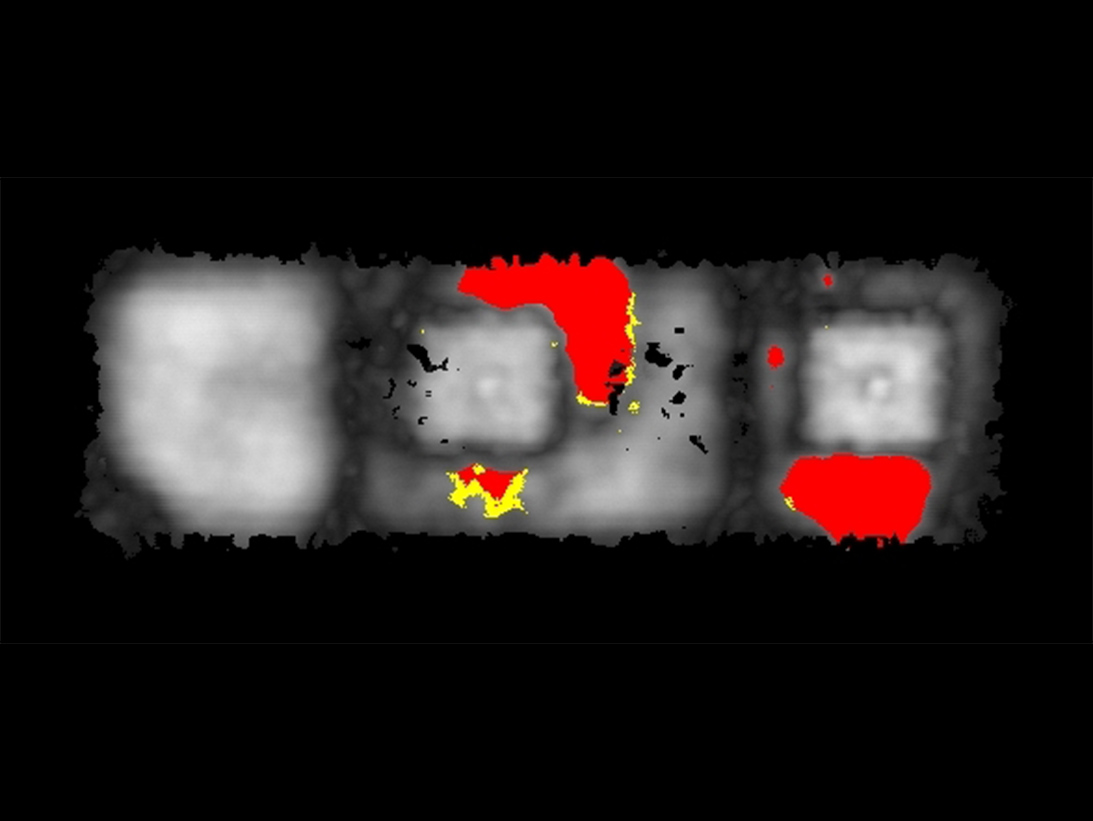

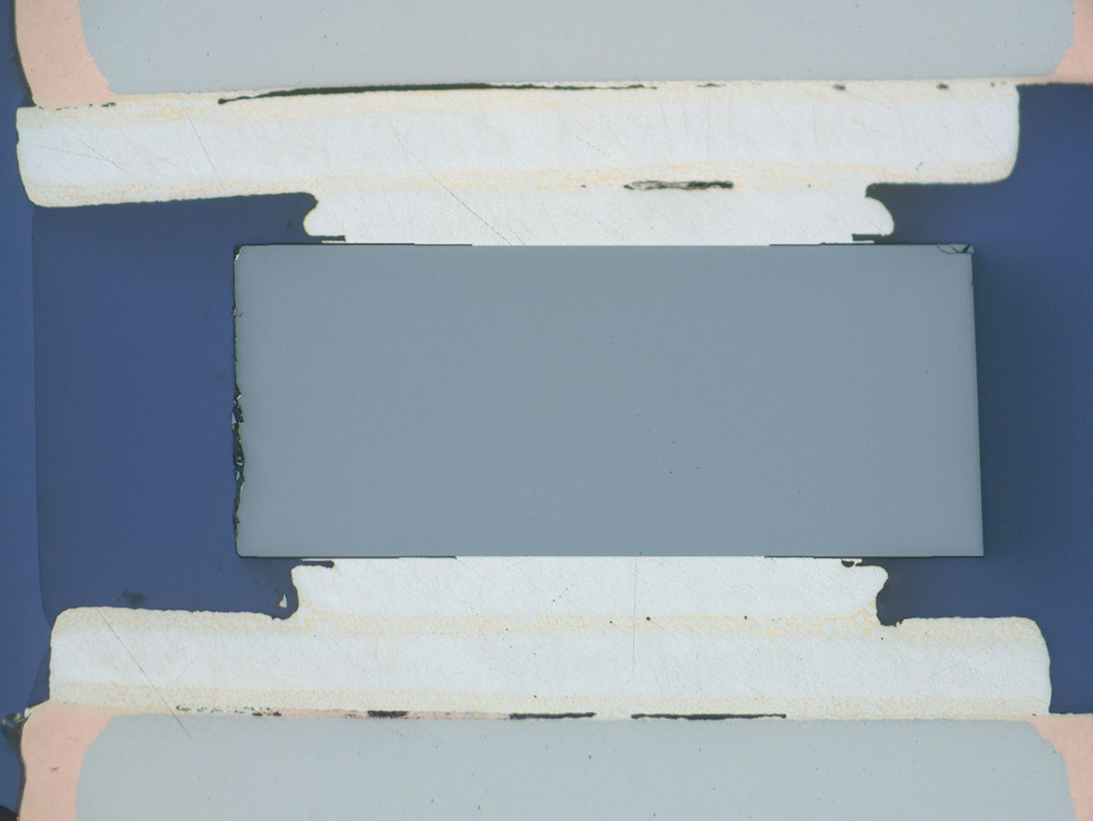

Plastic encapsulated devices require acoustic microscopy, dye impregnation, cross-sectional inspection, bond pull (if applicable) and SEM metal inspection, depending upon metallization pattern.

Destructive Physical Analysis

ORS has over 40 years of experience performing comprehensive testing designed to identify anomalies that can lead to field failure.

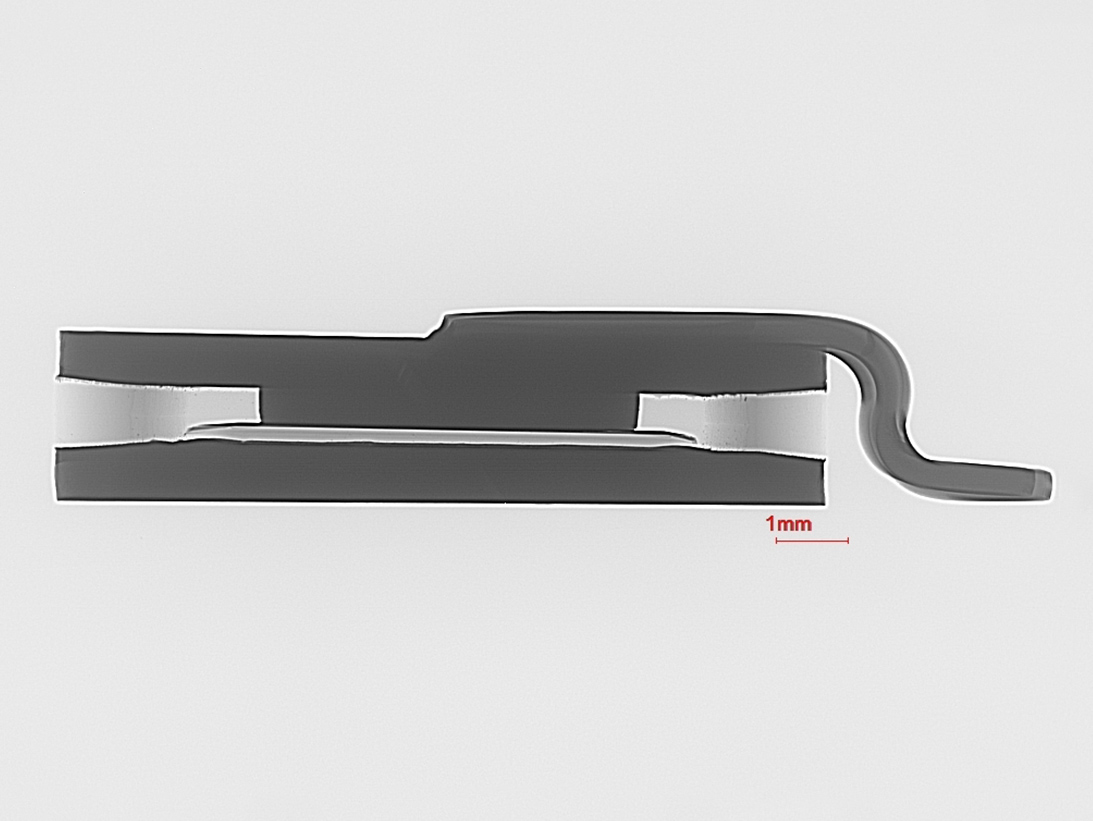

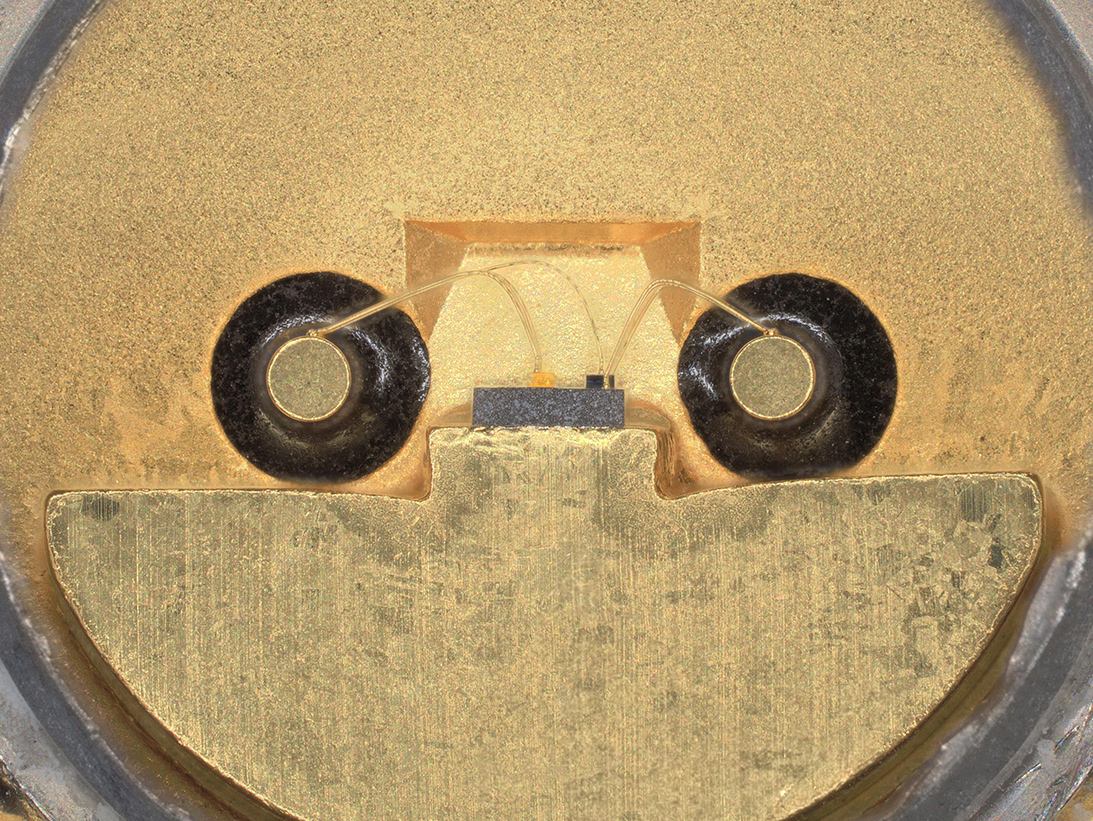

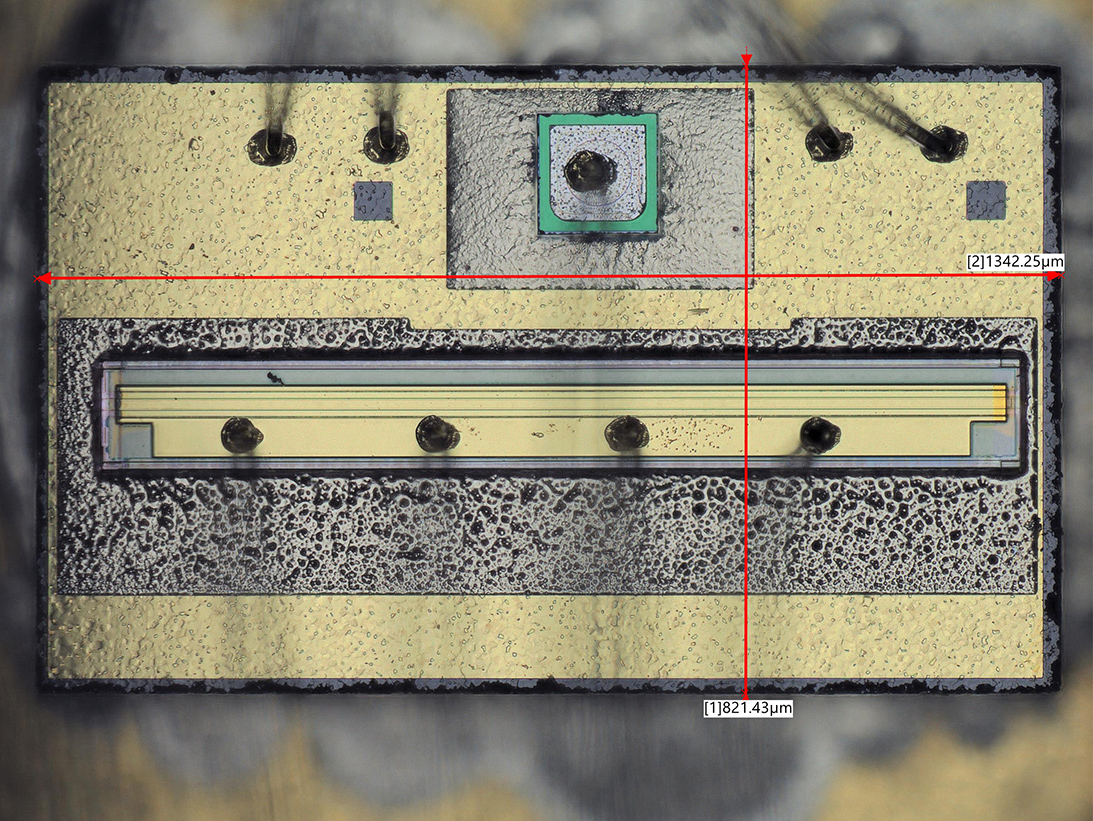

ORS DPA techniques for diodes may include hermeticity testing with cross-sectional analysis and dye penetrant – to assess glass to metal seals or epoxy mold compound adhesion to surface breaking features to reveal moisture sensitivity concerns. Cross-sectional planes are used in the examination of critical features such as dye attachment, wire bond formations with assessment of intermetallic growth in bi-metallic systems, effective secondary bonding/placement, dye attachment coverage and fillet formation including silver flake dispersion. Internal gas analysis (IGA) for hermetic devices may be necessary.

*Copper bond wires are increasingly used and encountered in plastic encapsulated devices that require refined de-encapsulation techniques to prevent de-processing damage that could skew test results.

Contact us for information about diodes testing

Non-Destructive Test Methods

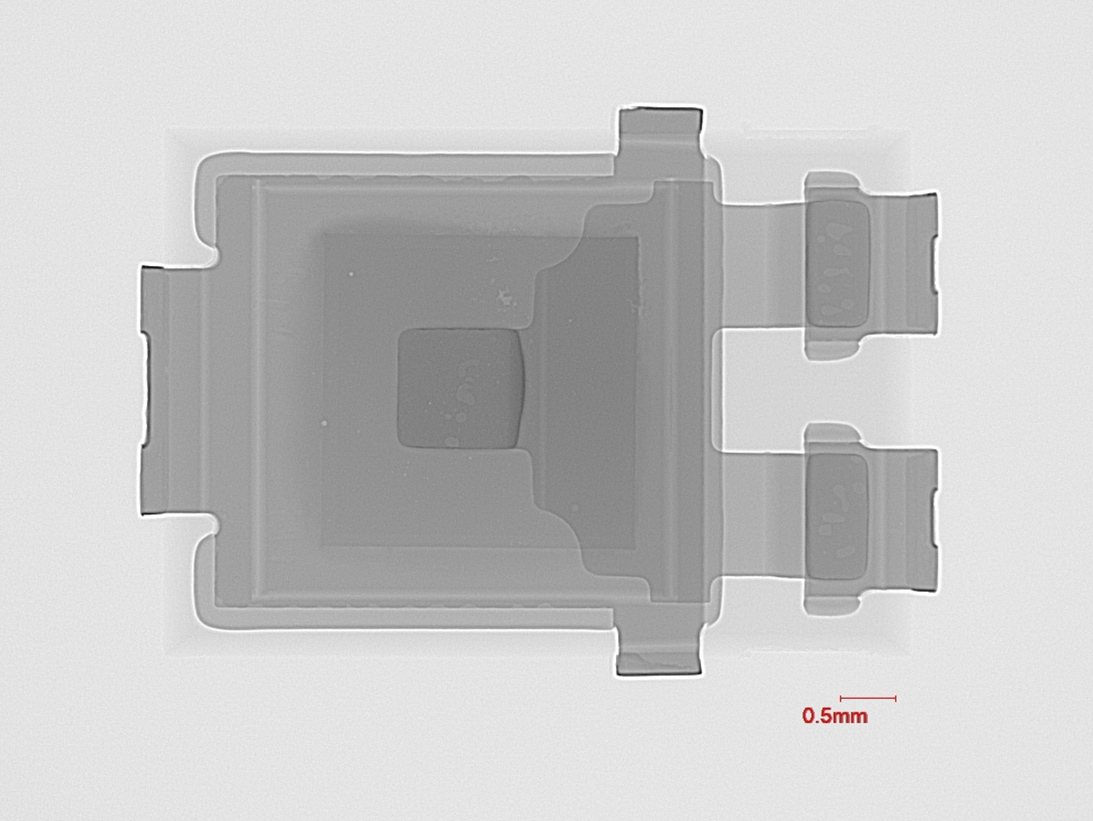

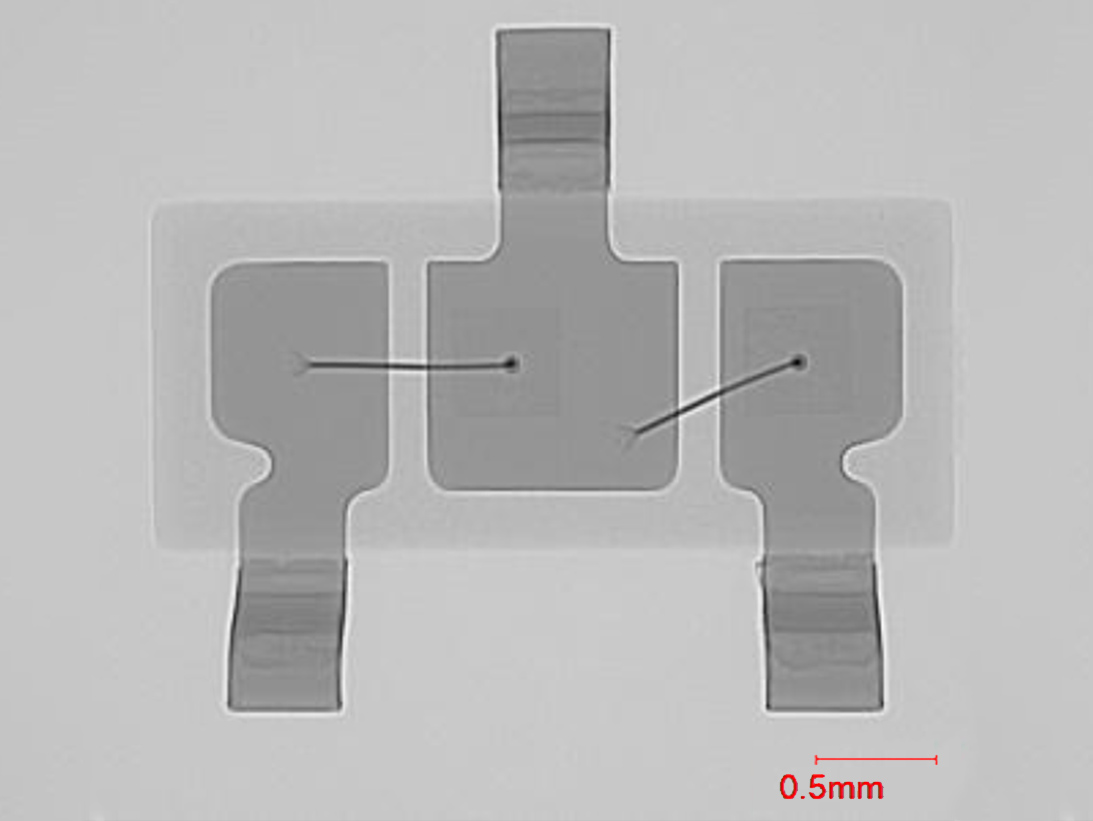

An important part of a diode DPA are the applicable initial non-destructive test methods – external visual inspection with physical dimensions/configuration compliance, X-ray radiography, electrical testing, acoustic microscopy, hermeticity, particle-induced noise detection (PIND), prohibited material analysis (PMA) by X-ray fluorescence elemental analysis (XRF) along with Fourier transform infrared microscopy (FTIR)*.

*FTIR is commonly included in baseline DPA or Construction Analysis (CA) type analyses to document functional groups detected in mold compounds and other organic features (i.e., dye conformal coating and lead-frame adhesives).

External view of Glass

Axial X-ray view of Diode

Diode termination end views

PED TO-277A

Y-axis X-ray view

Z-axis X-ray view

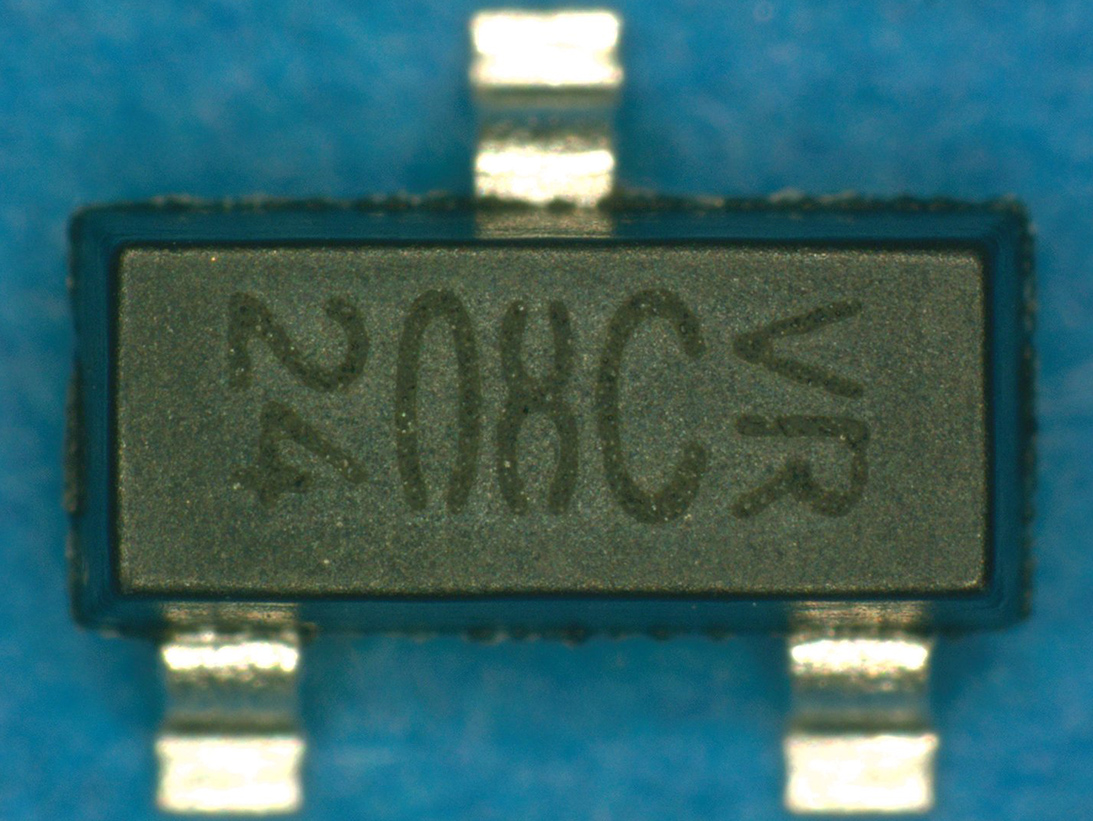

Optical image of Diode dye in SOT-23

X-ray of dual diode dye

Acoustic image of PED

Part Markings

Z-axis X-ray image

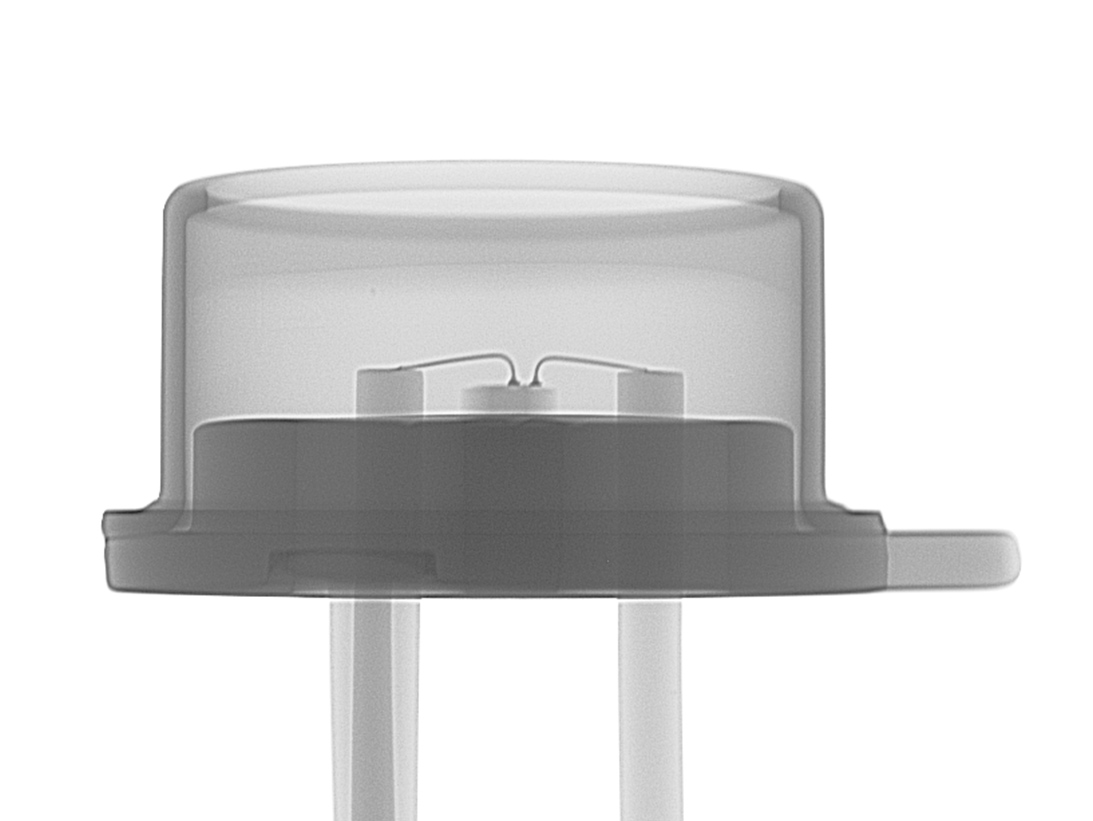

X-ray image of TO-can

Images of Destructive Analysis Methods of Diode Testing

A complete DPA of a diode could include destructive test methods such as IGA – internal gas analysis, internal visual inspection achieved by de-lidding/de-encapsulation or by cross-sectioning, bond strength testing, and scribe and break methods. Diode dye with expanded metal require scanning electron metal inspection (SEM). SEM with energy dispersive X-ray (EDS) analysis may be utilized for internal prohibitive materials analysis testing.

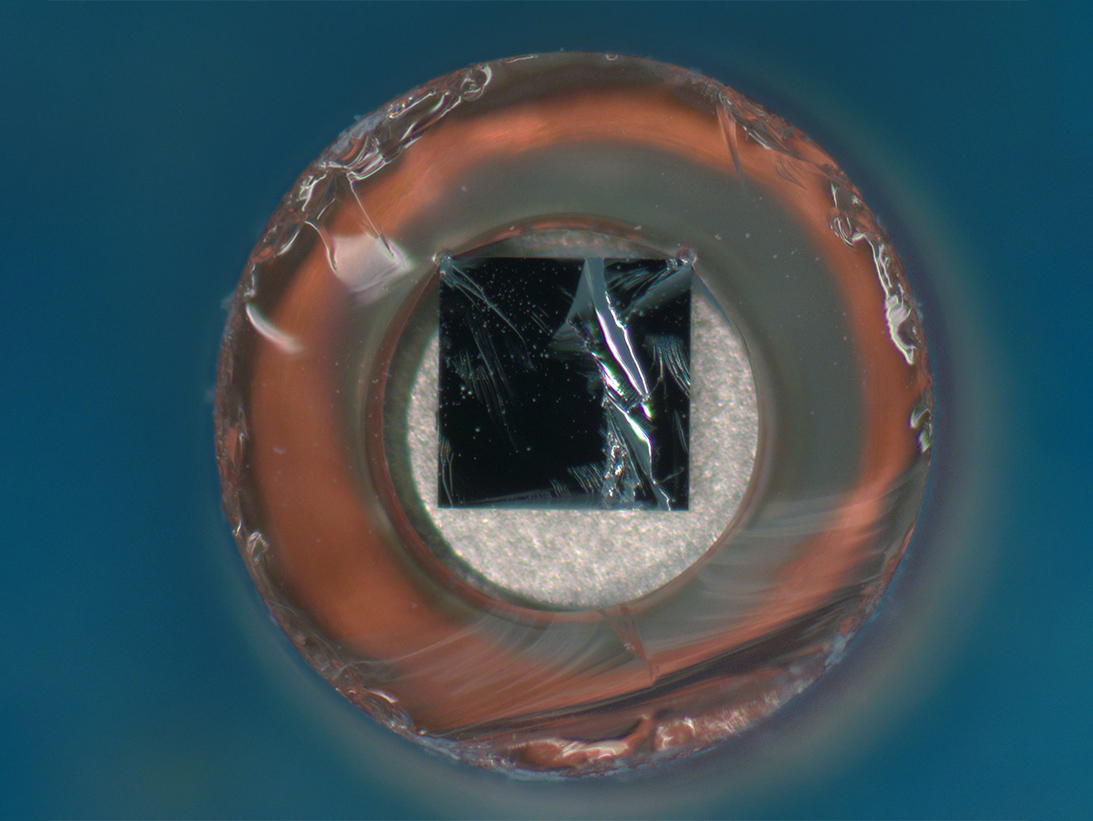

Internal visual inspection thru-glass

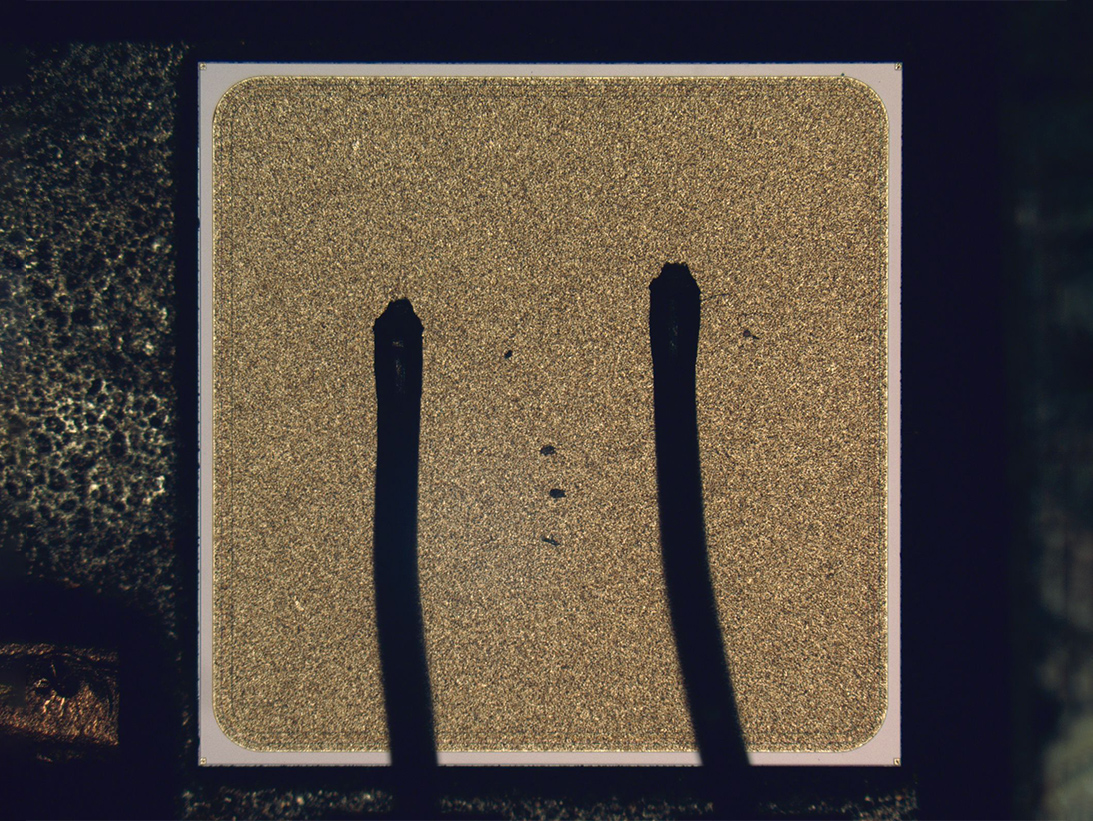

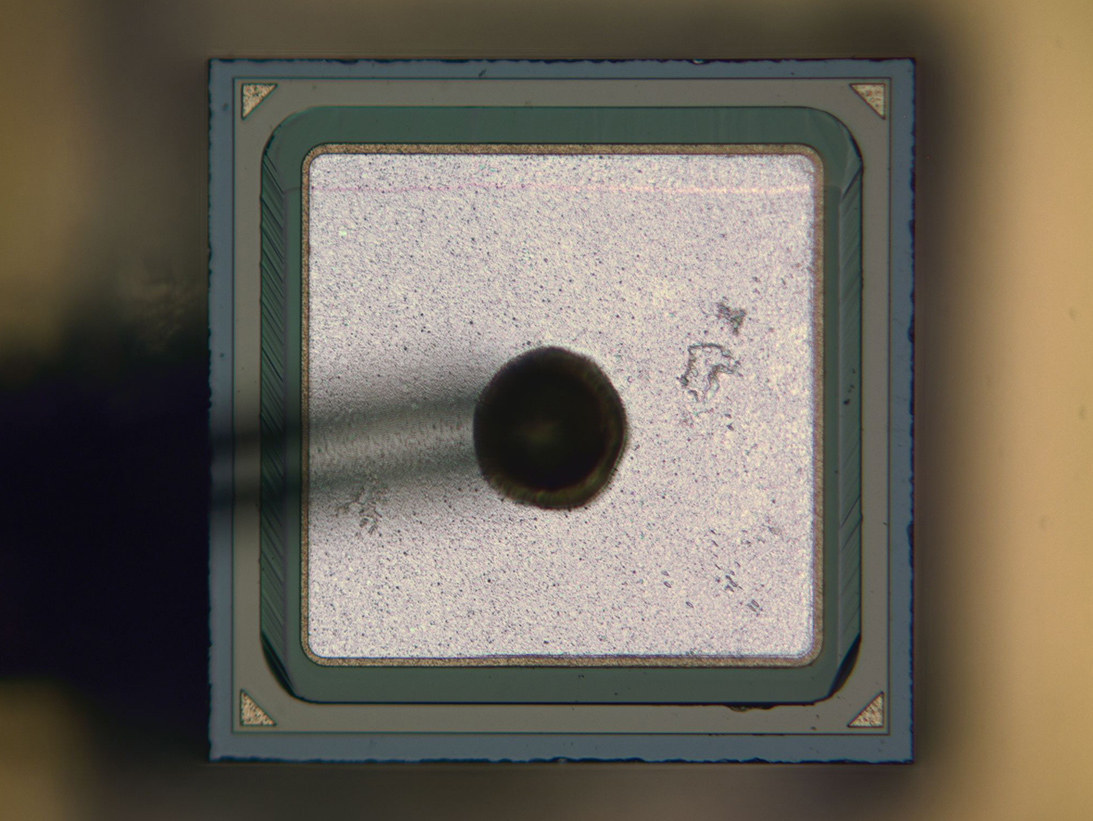

Cross-sectional view of diode dye

Scribe and break dye attachment evaluation

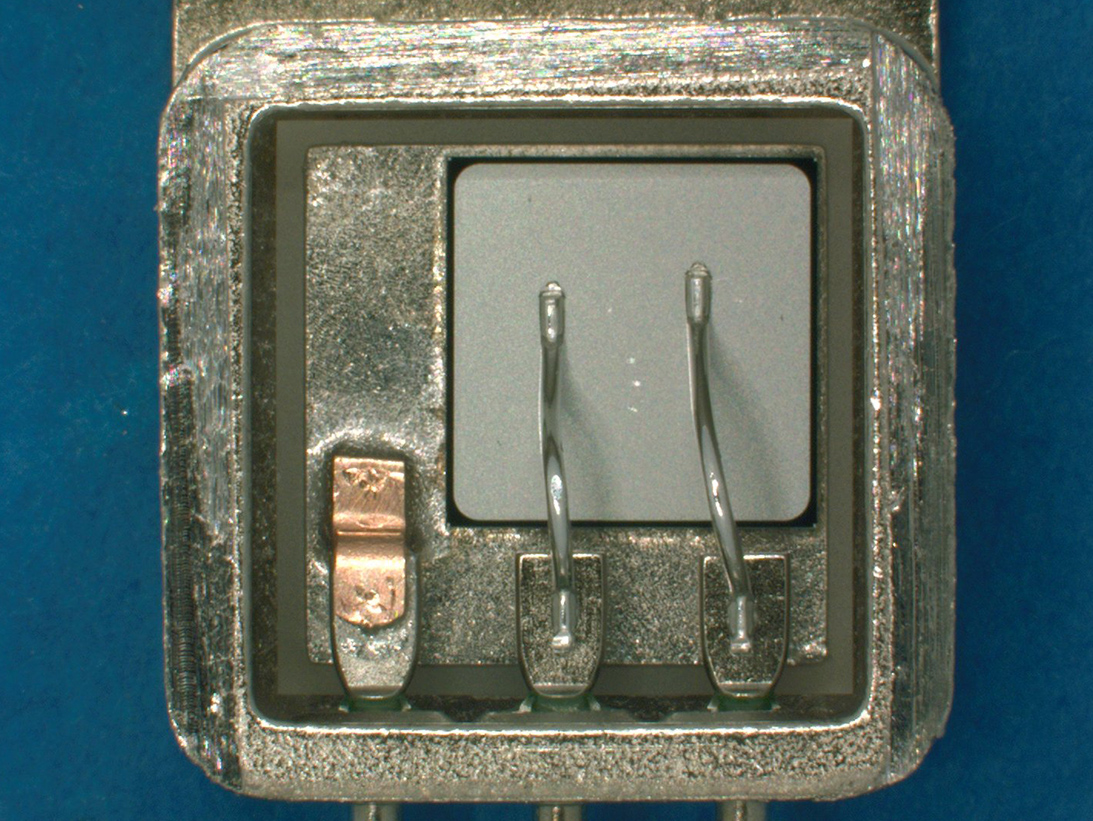

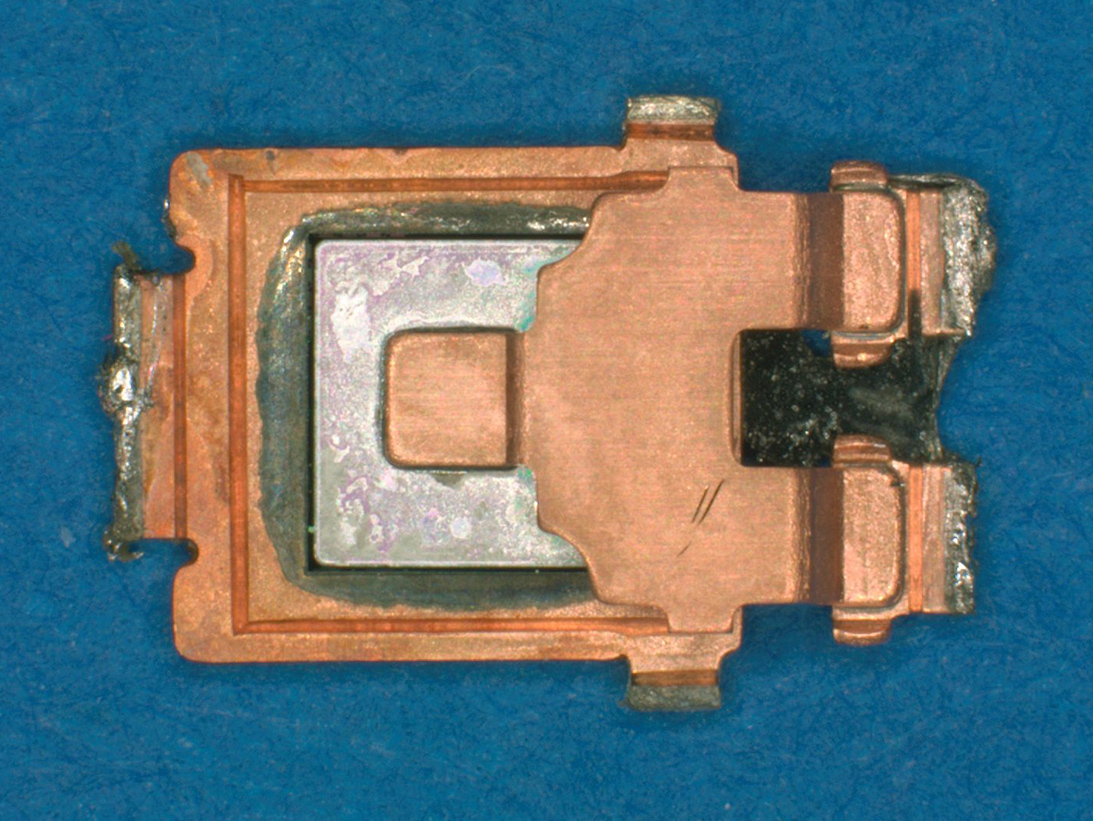

Internal cavity view De-lidding by MIDAS

Overall dye view

Internal cavity view

Internal view of TO-277A Laser/Acid decapsulation

Overall planar dye

Diode dye in active device

Failure Modes of Diodes that can be revealed by DPA:

Failure modes of diodes will depend and vary on construction and by application

- Loss of hermeticity/EMC delamination/moisture sensitivity/glass seals

- Wire bonding damage/ bimetallic intermetallic compound

- Dye scribing defects

- Pure tin at external surfaces and internal surface

- Undisclosed product changes

Applicable Industries:

- Space

- Aerospace

- Military Terrestrial

- Automotive/Commercial

- Mainframe Computers

Military Standards:

- MIL-PRF-19500

- MIL-STD-1580/Req 13

- MIL-STD-750 various Methods

Summary of Diode Testing Methods

MIL-STD-1580 Requirement 13

MIL-STD-750 Test Methods 2101/2012

- External Visual

- Physical Dimensions

- Lead Finish Verification

- X-ray Radiography Method 2076

- Acoustic Microscopy J-STD-035

- Dye Impregnation

- Internal Visual Inspection Method 2073

- De-encapsulation

- Cross-section

- Bond Pull Testing Method 2037

- Bond Shear Testing Method 2037

- SEM Metal Inspection Method 2077

- Prohibited Materials Analysis Req. 9