Gross Leak Hermeticity Testing Processes

HSHLD™ Dry Gross Leak

The HSHLD™ gross leak test method uses the oxygen signature and pressure change caused by a gross leaking device to screen for failures. The device under test is compared to a known good sample of the same volume; this comparison will reveal the presence of a leaking device. Please visit our HSHLD™ MODEL 310 Hermeticity Testing page for more information.

Per-Fluorocarbon Gross Leak

A device with a gross leak could theoretically pass the standard Helium fine leak test. Therefore, this test is typically performed after fine leak. Depending on the requirement of the specification being followed, gross leak may be performed by two different methods.

- The device is submerged in an indicator fluid tank at a specified high temperature of 125C, and observed for evidence of bubble stream emanating from a gross leak site. A lower temperature may be used depending on device material constraints.

- The test may require preconditioning in a pressurized chamber filled with an inert detector fluid that characteristically has a low boiling point. After preconditioning, the devices are submerged in an inert indicator fluid with a higher boiling point. In theory, any detector fluid located within the internal cavity of the package would boil when exposed to the high temperature of the indicator fluid, thus creating a bubble stream from the gross leak site.

Krypton-85 Dry Gross Leak

This test is typically performed prior to Fine Leak testing as a method of eliminating failures that would otherwise trap large amounts of radioactive Kr85 through longer term Fine leak pressurization. Visit our Krypton-85 page for more information.

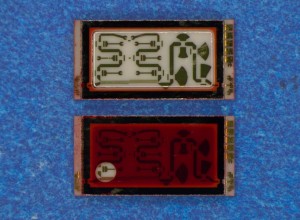

Krypton-85 Wet Gross Leak

A large leak path can be deceiving to tracer gas detection. During the testing of a small cavity device it is possible for the tracer gas to escape giving the illusion of a passing device. Using the Kr-85 wet gross leak method dye is used to slow the movement of gas through the leak path while also creating a visual cue for leak site identification. This method is required in Mil-Standard Kr-85 testing for devices with a cavity <0.1cc. Visit our Krypton-85 page for more information.