Temperature Cycle Testing

Temperature Cycling or Thermal Cycle testing is performed on materials to determine the resistance of exposure to alternating extremes of high and low temperatures. Thermal mismatch of materials can cause solder joint cracking, warpage, damage to leads and markings, and hermetic seal failures.

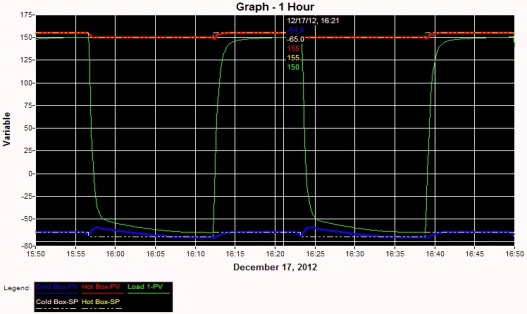

Powered Temperature Cycling (PTC) uses the same extreme temperature exposures as traditional temperature cycling but with the addition of simultaneous operating and electrical biases periodically applied and removed. PTC is used to simulate the worst case conditions in application environments.

Adhesives such as silicones, epoxies and polyurethanes can also be tested for thermal cycling resistance where the bonded materials may have different coefficients of thermal expansion and contraction. Conducting temperature cycling tests on these components will assist in determining:

- The existence of thermal coefficient mismatches

- The sensitivity of these mismatches to repeated temperature excursions

Oneida Research Services offers a range of temperature cycle test services to simulate different scenarios.

- Temperature Cycle Test Specifications / Standards

- GR-468-CORE

- JESD22-A104

- MIL-STD-750 Method 1051

- MIL-STD-750 Method 1055

- MIL-STD-883 Method 1010

- Power Temperature Cycle Test Specifications / Standards

- JESD22-A105

- MIL-STD-883 Method 1007

Test conditions vary based on the type of sample being tested. Specific temperature cycling rates and other test conditions for components, boards, solder interconnects and/or tin whisker evaluations can be specified. The temperature cycle test is performed in chambers that control the number of cycles, dwell times, transfer times or ramp rates. Elevator-type chambers are used when ramp rates between the low and high temperature extremes must occur at a fairly rapid rate, like with MIL-STD-883 method 1010. If a slower ramp rate between temperature extremes is required, a single temperature cycle test chamber is best suited. By using a single-chamber piece of equipment, a specified, slower ramp (for example, 10°C per minute) can be set.