Failure Analysis

Test Methods

- Ball Shear Strength

- Bond Strength

- C-SAM

- Damp Heat Storage

- DC I.V. Curve Tracing

- Die Back Metallization

- Die Shear Strength

- Digital Microscopy

- Dye Impregnation

- Elemental Analysis

- External Visual Inspection

- Fluorescence Microscopy

- Glassivation Layer Integrity

- Glassivation Thickness

- Hermeticity Testing (3,4)

- High Resolution Film X-Ray

- Internal Vapor Analysis (IVA™)

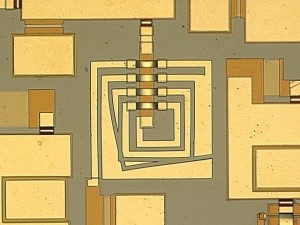

- Internal Visual Inspection

- Metallization Thickness

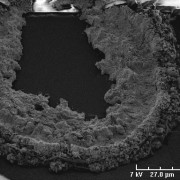

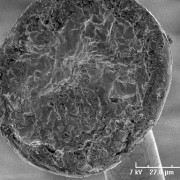

- Micro Cross-Sectioning

- Nitric and Sulfuric Decapsulation

- Particle Impact Noise Detection

- Scanning Electron Microscopy (SEM) Inspection

- SEM Metallization Inspection

- Solder Reflow/Moisture Sensitivity Testing

- Sub-Micron Real Time X-Ray

- Via Metallization

- Wafer Thickness

Failure Analysis is an investigative logical process of analytical methodologies designed to determine the root cause of a failure mode. Failure analys is can provide detailed information regarding the performance of materials, components/devices and systems in their intended end use application. When a device or material does not meet its performance expectations, a failure analysis should be performed to identify the root cause of failure. The information presented in the root cause failure analysis will allow the product designer and manager, as well as the test and process engineers, to identify design, selection, test, and process deficiencies. Recommendations for corrective actions from the failure analysis report can then be evaluated and implemented to enhance product reliability and performance. Having an unbiased failure analysis report performed by an independent testing laboratory, the liability of a failed device or material can be converted into an asset, resulting in production of higher quality products.

is can provide detailed information regarding the performance of materials, components/devices and systems in their intended end use application. When a device or material does not meet its performance expectations, a failure analysis should be performed to identify the root cause of failure. The information presented in the root cause failure analysis will allow the product designer and manager, as well as the test and process engineers, to identify design, selection, test, and process deficiencies. Recommendations for corrective actions from the failure analysis report can then be evaluated and implemented to enhance product reliability and performance. Having an unbiased failure analysis report performed by an independent testing laboratory, the liability of a failed device or material can be converted into an asset, resulting in production of higher quality products.