Destructive Physical Analysis (DPA)

Testing Options

- Mil-Std-883

- Mil-Std-750

- Mil-Std-1580

- Mil-Std-202

- Ball Shear Strength

- Bond Strength

- DC I.V. Curve Tracing

- Die Shear Strength

- Digital Microscopy

- External Visual Inspection

- Fluorescence Microscopy

- Glassivation Layer Integrity

- High Resolution Film X-ray

- Sub-Micron Real Time X-ray

- Internal Visual Inspection

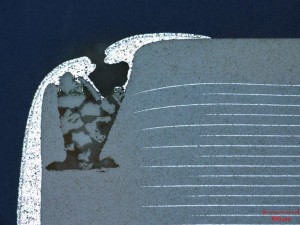

- Cross-Sectioning

- Particle Impact Noise Detection

- Scanning Electron Microscopy (SEM) Inspection

- SEM Metallization Inspection

- Solder Reflow/Moisture Sensitivity Testing

- Glassivation Thickness

- Metallization Thickness

- Hermeticity Testing

- SEM, XRF, and FTIR Elemental Analysis

- Scanning Acoustic Microscopy

(C Mode) - Ion Milling

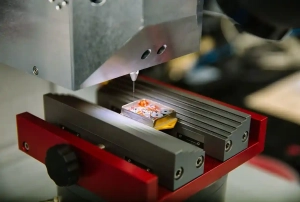

- Laser De-encapsulation

- Acid De-encapsulation

- Sample De-lidding

- Insulation Resistance

- Dielectric Withstanding Voltage

- Contact Retention

- Plating Adhesion

- Insulator Retention

Destructive Physical Analysis, also known as DPA, is an inspection program utilized by the aerospace and terrestrial military industries intended to perform two main functions. One is to perform a final audit to verify the device’s construction design and meet material performance specifications and secondly, to screen for lot related process/manufacturing deficiencies thereby preventing inconsistent reliability. DPA testing supplements or exceeds a manufacturer’s lot screening process. Manufacturers may catch non-functioning components prior to shipment, but destructive physical analysis is designed to be more rigorous than a manufacturer’s lot screening process.

Parts ORS does DPA testing on:

- Capacitors

- Connectors

- Crystals

- Diodes

- Filters

- Fuses

- Hybrids

- Magnetics (Transformer/Inductor)

- Microcircuits

- Plastic Encapsulated Microcircuits

- Relays

- Resistors

- Thermistors

- Transistors

DPA testing verifies and documents the quality of device construction through a complete tear-down disassembly of the device. By disassembling, testing, and inspecting a device, a complete profile can be created to determine how well a device conforms to design and process requirements. A complete Destructive Physical Analysis or DPA test flow typically consists of a systematic and progressive series of environmental and mechanical tests. The applicable DPA tests are typically covered under military standards, often referred to as a Mil-Std. It is important to remember DPA is not a test itself, but rather a comprehensive series of tests where the parts are examined for design, workmanship and processing issues.

The objective of DPA military standards is to apply proven technical practices that will result in improved quality and reliable devices for end-use. They are intended to provide the general framework and basis for Destructive Physical Analysis procedures.

Although several military test standards are available, only a handful are used for DPA testing. The two most common DPA military standards are; Mil-Std-883 test method 5009 and Mil-Std-1580.

Mil-Std-883 test method 5009 – Destructive Physical Analysis. This DPA testing standard is generally used for microcircuit and hybrid or multichip components intended for high reliability space applications. The series of tests referenced in this standard refer MIL-STD-883 tests only. This test standard does not give requirements for Prohibited Material Analysis (PMA).

Mil-Std-1580 – Department of Defense Test Method Standard – Destructive Physical Analysis For Electronic, Electromagnetic, and Electromechanical Parts. This standard is used to ensure the high quality of parts used in the design of space and launch vehicles. Mil-Std-1580 DPA testing standard covers the detailed requirements for a wide variety of commodities as well as requirements for Prohibited Material Analysis (PMA) per Requirement 9. Since this test standard covers several different commodities, it refers to other military test standards to aid in the test program. Mil-Std-883, Mil-Std-750, Mil-Std-202 and Mil-Std-981 are referenced within Mil-Std-1580.

ORS has over 40 years’ experience performing Destructive Physical Analysis and is well versed in DPA testing procedures. In addition to testing per Mil-Std-1580 and Mil-Std-883 method 5009, ORS is capable of performing client specified DPA test flows, either through a client’s selection of Mil-Std test procedures or a complete DPA performed to meet a client owned procurement document.