X-Ray Fluorescence Elemental Analysis

X-Ray Fluorescence Elemental Analysis is an analytical technique used to perform elemental identification of materials. This technique is similar to Scanning Electron Microscopy/Energy Dispersive X-Ray Analysis (SEM/EDX), which is also used to perform elemental analysis. XRF is preferred for ease of use and for non-conductive material applications such as plastics, ceramics, glasses, and liquids.

X-Ray Fluorescence Elemental Analysis is an analytical technique used to perform elemental identification of materials. This technique is similar to Scanning Electron Microscopy/Energy Dispersive X-Ray Analysis (SEM/EDX), which is also used to perform elemental analysis. XRF is preferred for ease of use and for non-conductive material applications such as plastics, ceramics, glasses, and liquids.

Information Obtained and Applications

- Qualitative Bulk Analysis – Solders, metals, jewlery, plastics, ceramics, powders and liquids

- Film or plating Analysis – Composition and thickness of PCB/PWB metallization schemes Au/Ni/Cu

- Quantification of elemental composition including phosphorous content in Nickel

- Identify anomalies/defects and possible causes

- RoHS and prohibitive materials mitigation

Instrument Sensitivity/Capabilities

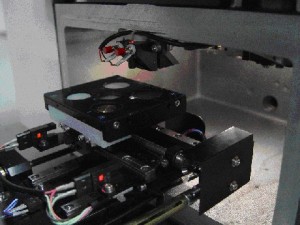

- SEA 5120 Ultra Thin Window Si(Li) Detector

- Qualitative/Quantitative analysis of microscopic objects (100µm level)

- Detection and identification of elements Al -> U

- A video display and frame capture capabilities of sample

- Three collimators: 4-mil, 80-mil, and 80-mil with a Mo filter

- Tube voltage from 15, 45 or 50kV

- Elemental analysis and thick measurements of multiple layers

- Sample size 80mm(W) x 80mm(D) x 35mm(H). Max weight 3kg