ASTM E595 Outgassing Services

Introducing ASTM E595 Outgassing Testing by Oneida Research Services

At Oneida Research Services, we are thrilled to announce the addition of ASTM E595 testing for outgassing to our comprehensive suite of services. This essential test method, vital for ensuring material compatibility in space environments, is now available to our esteemed clients.

What is ASTM E595?

Industries like aerospace, electronics, semiconductors and others relying on vacuum environments require rigorous material screening. The ASTM E595 test method plays a vital role, offering a standardized way to assess a material’s outgassing properties. For example, the test can characterize outgassing properties for components in non-hermetic packages like underfilled BGAs (Ball Grid Arrays) and parylene-coated plastic parts.

ASTM E595 simulates space-like conditions by exposing materials to a vacuum and elevated temperatures (typically 125°C). This test measures two key parameters:

Total Mass Loss (TML): It quantifies the total amount of material that evaporates or releases gasses (outgassing).

Collected Volatile Condensable Materials (CVCM): It measures the specific volatile organic compounds (VOCs) that condense under these conditions. VOCs pose a high contamination risk in sensitive environments like spacecraft and cleanrooms.

Test Procedure

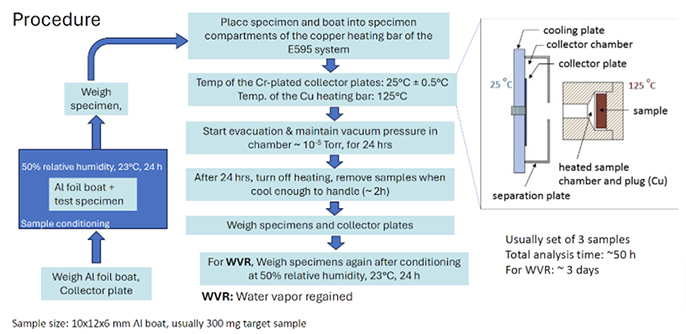

ASTM E595 screening requires a well-defined test procedure and apparatus to determine the volatile content of materials when exposed to a vacuum environment. The test procedure can be summarized as follows:

- Preconditioning of samples: Materials are conditioned for humidity and temperature (e.g., 50% relative humidity at 23°C for minimum of 24h).

- Vacuum exposure: After preconditioning, samples undergo a 24-hour exposure to a defined vacuum level (i.e., 5 × 10-5 Torr) at 125°C for 24h. Collector plates are maintained at 25°C during the vacuum exposure.

- Accurate TML measurement: The net weight change of the sample before and after testing is measured.

- CVCM quantification: The weight gain of a collector plate capturing condensed VOCs is measured to quantify CVCM.

Request a Demo or Follow-Up Call

Samples

Organic, polymeric and inorganic materials, such as:

- Polymer potting compounds

- Foams

- Elastomers

- Films

- Tapes

- Insulations

- Shrink tubing

- Adhesives

- Coatings

- Fabrics

- Tie cords

- Lubricants

Applications of ASTM E595 Testing

Aerospace:

Ensuring materials used in spacecraft and satellites meet stringent outgassing requirements to prevent contamination and failure of sensitive components.

Electronics:

Testing materials for printed circuit boards, electronic assemblies and avionics to prevent outgassing that could damage electronic components or compromise internal gas composition that can result in failing internal gas analysis as defined in MIL-STD 883, test method 1018.

Optics:

Ensuring materials used in optical systems, such as lenses and mirrors, do not outgas and degrade optical performance.

Defense:

Testing materials for military equipment and defense systems to ensure reliability and performance in high-vacuum environments.

Medical Devices:

Ensuring materials used in medical devices meet outgassing standards to prevent contamination and ensure patient safety.

Research Laboratories:

Conducting experiments and research that require materials to be tested for outgassing properties in vacuum environments.

Why Choose ORS for ASTM E595 Testing?

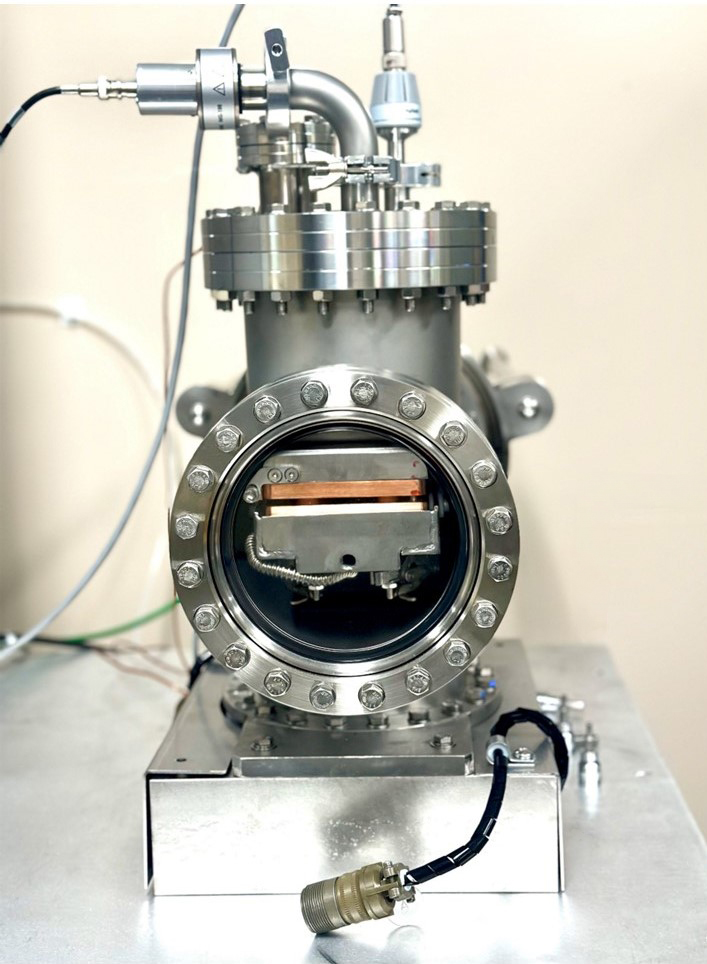

Oneida Research Services is equipped with state-of-the-art testing facilities and a team of experienced professionals to deliver accurate and reliable ASTM E595 testing. Our capabilities include:

- Advanced Testing Equipment: We utilize cutting-edge technology to conduct precise outgassing measurements.

- Detailed Reporting: Comprehensive reports provide insights into the material properties and compliance with ASTM E595 standards.

- Expert Consultation: Our team of experts is available to discuss your specific testing needs and provide tailored solutions.

Beyond ASTM E595 screening, we offer a comprehensive range of complementary services, including high-temperature ultra-high vacuum evolved gas analysis, material outgassing studies, thermal properties measurement and gas chromatography/mass spectrometry (GC/MS). At ORS, we understand the importance of timely results. Our streamlined processes ensure you receive your test results quickly, enabling you to make informed decisions without delay.