E595 Model 610 Outgassing Test System for ASTM

The E595 Model 610 represents the next generation of outgassing test technology from Oneida Research Services, Inc. Built on decades of leadership in Residual Gas Analysis (RGA) and hermetic test equipment manufacturing; the E595 Model 610 delivers a fully automated, highly repeatable solution for determining the volatile content of materials exposed to vacuum environments.

Designed specifically to perform the ASTM E595-15 (2021) test method, the system measures Total Mass Loss (TML), Collected Volatile Condensable Materials (CVCM), and Water Vapor Regain (WVR) with exceptional precision. The Model 610 integrates advanced vacuum hardware, intuitive icon-driven software, and a streamlined sample handling architecture to provide unmatched ease of use and throughput.

Purpose-Built for ASTM E595 Outgassing Qualification

The E595 Model 610 is engineered from the ground up to support the stringent requirements of aerospace, defense, electronics, and high-reliability manufacturing. The system automates every step of the outgassing experiment – from vacuum cycling and temperature control to data acquisition and report generation – ensuring consistent, reproducible results across all specimens.

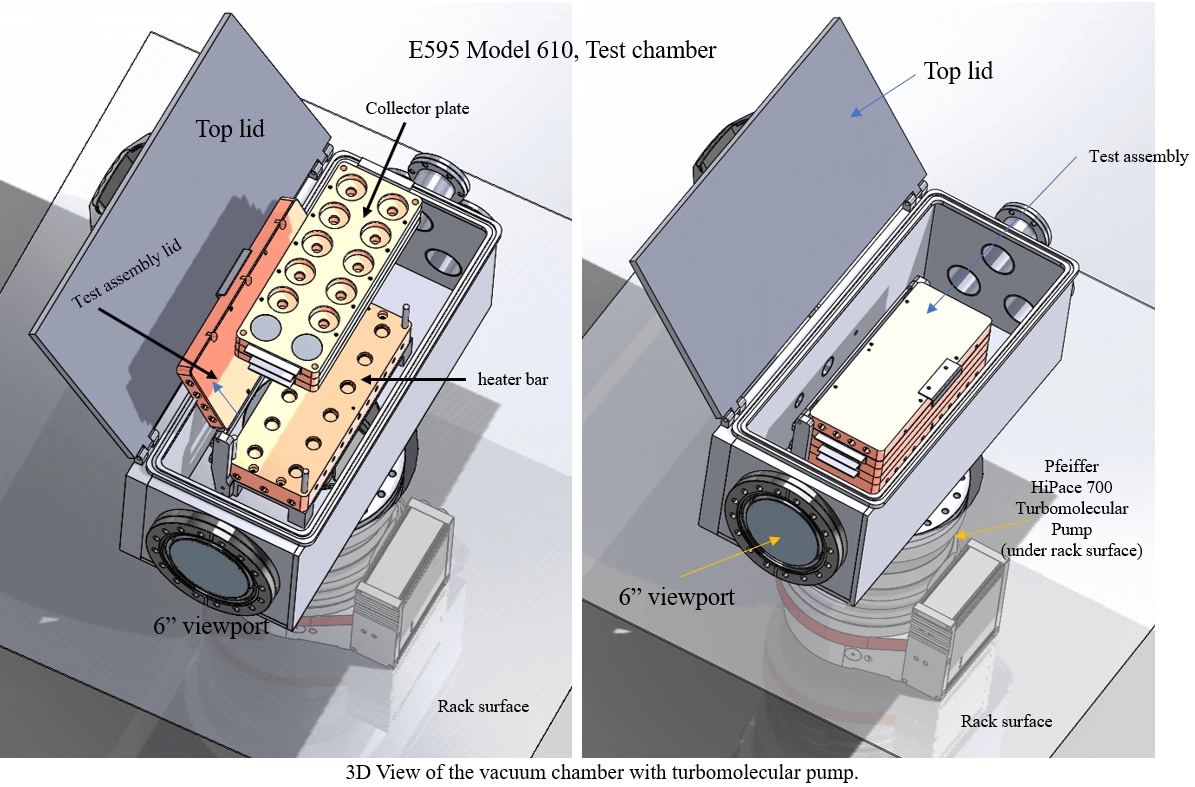

With capacity for 12 samples in one batch, the Model 610 meets the full ASTM E595 configuration while offering a compact footprint and optimized chamber geometry for effortless loading and unloading.

Key Features

Comprehensive ASTM E595 Testing

- Measures TML, CVCM, and WVR in full compliance with ASTM E595-15 (2021).

- Integrated hardware and software designed specifically for outgassing characterization.

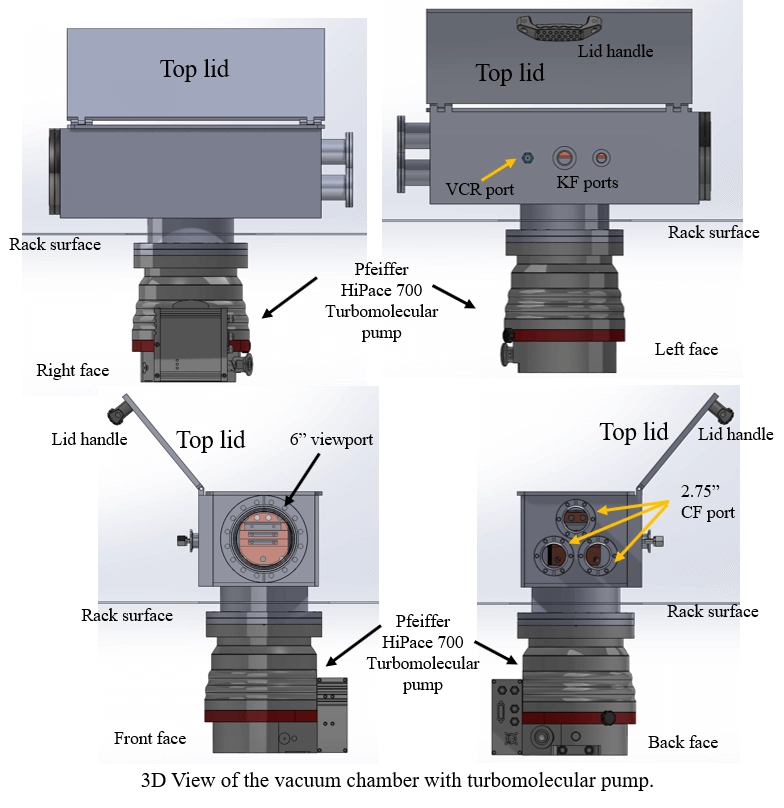

High-Performance Vacuum Architecture

- Ultra-high vacuum capability supported by a turbo pump and oil-free dry screw pump.

- Clean, stable vacuum environment ensures accurate and repeatable measurements.

Advanced, Icon-Driven Software

- Intuitive interface designed for rapid learning and streamlined workflow.

- Built-in data analysis tools and automated publication-grade report generation.

- Complete system control from a single software environment.

Cooling-Enabled Heating Bar

- The only system in its class with active cooling for the heating bar, reducing turnaround time between tests and increasing daily throughput.

Fully Automated Operation

- Automated control of vacuum cycling, pressure regulation, temperature profiles, and data collection.

- Minimal operator intervention – load samples when prompted, and the system manages the rest.

12-Specimen Capacity

- Accommodates 12 sample compartments and 12 condensable-material collectors as specified by ASTM E595.

- Optimized chamber layout for efficient sample handling and improved ergonomics.

Optimized Footprint and Sample Handling

- Smaller footprint than competing systems, with superior chamber geometry for easy access.

- Single-action load/unload capability simplifies operation and reduces handling time.

Turnkey Installation & Training

- On-site installation, system validation, and operator training included with every instrument.

- Backed by ORS’s industry-leading expertise in hermeticity and outgassing analysis.

A Complete, Modern Solution for Outgassing Qualification

The E595 Model 610 brings together ORS’s deep experience in vacuum science, materials evaluation, and automated instrumentation. Whether qualifying materials for spaceflight, high‑reliability electronics, or advanced packaging applications, the Model 610 provides a robust, user‑friendly platform for accurate and repeatable outgassing measurements.