DELTA-P MODEL 410 GETTER SORPTION ANALYZER

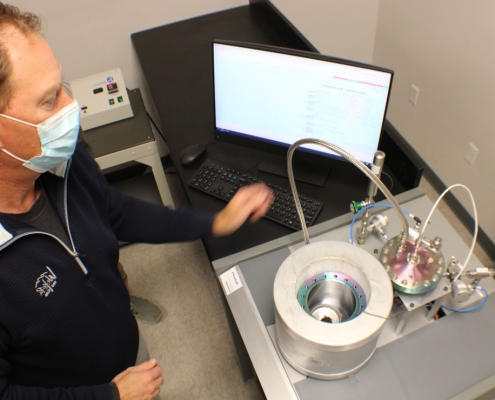

ORS manufactures the Delta-P Model 410 for companies that want to perform on-site getter qualification and lot conformance testing.

Having an in-house getter analysis system is ideal for conducting internal research and developing proprietary compounds. ORS can customize your Delta-P 410 system to fit your precise gas, vapor, material, temperature or pressure requirements. This includes different chamber size options to match your testing needs.

Getters are reactive materials that are placed inside closed systems to maintain a vacuum or other desired gas composition. Carefully testing getter materials provides safer operational environments for medical devices, microelectronics, cryogenics and energy storage systems.

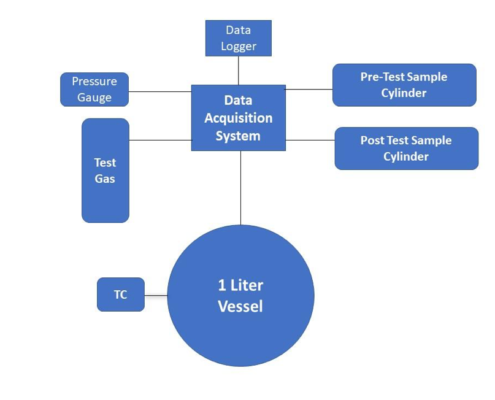

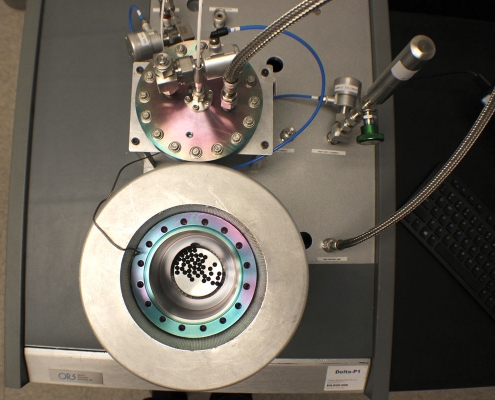

The Delta-P 410 includes a test chamber, a data acquisition system, a variety of sensors, and the necessary plumbing to introduce, vent and sample test gases.

Methods for Testing Getters

The Delta-P 410 lets you examine what happens when you expose getters to different types of gas and environmental variables. You’re able to visualize how the material may react at high or low pressure as well as high or low temperatures. The Delta-P 410 also gives you the instrumentation you need to perform long-term studies.

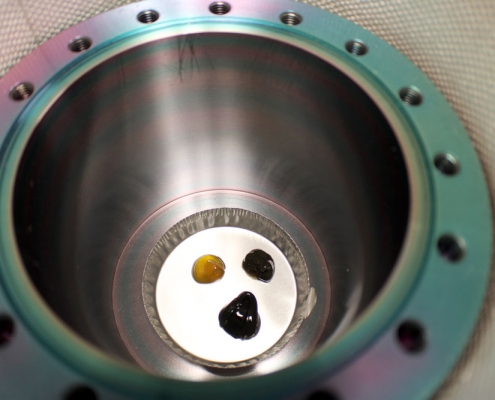

Getters can be produced in a solid, paste, slurry or powder form and can be shaped and molded as desired. They can be housed inside plastics or hermetic modules – often in very small spaces due to the limited free space inside devices (e.g., a pacemaker).

For testing, you can add any mixture of materials to your getter to see how they interact with it and affect its efficiency. You can add a gas or liquid as well as all kinds of chemical compounds.

Depending on the intended use, a getter may need to function at different sorption rates over short or long periods of time. A getter might need to sorb gas steadily over a long period of time or at an initial high rate of sorption (so the device is not affected), followed by an extremely slow sorption rate afterward.

A major concern for high reliability device manufacturers is moisture or hydride formation in components when hydrogen is present in the cavity. Getters are a primary solution used to mitigate the risk associated with these potential reactions.

How To Conduct Tests

To conduct tests, simply seal the weighed getter in the test chamber that is set at a designated temperature. The gas is purged or evacuated and re-filled to the selected pressure. Pressure and temperature data is collected for a specified duration (based on an estimated sorption rate) to obtain a proper sorption curve. For hydrogen getters, it’s important to introduce a 3% or lower certified hydrogen test gas mix into the vessel at a specified pressure. This ensures that the hydrogen concentration in the test system is below 4% – the lower flammability limit for hydrogen.

You can determine hydrogen sorption rates by measuring the change in pressure or Delta-P in the test chamber with constant volume and temperature over time. Delta-P Sorption Testing is applicable for three primary types of hydrogen sorption:

- Hydride Sorption where hydrogen is absorbed into a metal through gettering

- Sorption by Reduction where a metal oxide reacts with hydrogen to create a pure metal and water vapor

- Hydrogenation Sorption where hydrogen is absorbed into a getter to counteract the creation of water vapor

Delta-P Test Conditions

- Temperature: -40C to 400C

- Fill Pressure: 0 torr to 1520 torr

- Chamber Volume: < 1 Liter

Delta-P Test Results

- Initial, transitional and long-term sorption rates

- Getter sorption capacity

- Quantity of hydrogen sorbed

- Pre- and post-test gas analysis results utilizing Internal Vapor Analysis

- Results in cc/g or cc/cm2 (at Test Conditions or STP)

Complete the form on this page for more information to get in touch with us about developing a custom getter testing system for your unique applications.

Request a Delta-P Getter Sorption Demo or Call

Find out how to develop proprietary compounds by performing getter qualification and lot conformance testing at your facility. Complete this form and we’ll show you just how easy it is.